Cutting Mechanisms and Structural Design: How Tricone and PDC Drill Bits Work

Rolling Cone Action of Tricone Bits: Crushing Rock Through Mechanical Force

Tricone drill bits feature three spinning cones that have either tungsten carbide inserts or steel teeth for breaking up rock using compression. When the drill string turns, these cones actually spin separately on their own bearings, which creates both grinding and impact forces that break apart different rock layers. The design works particularly well when drilling through mixed ground conditions where there are patches of soft material next to harder sections. Adaptability matters a lot in these situations. What makes tricone bits stand out is how their teeth fit together and the way the cones are positioned relative to each other. This setup stops the bit from getting clogged up when working through sticky shales or clays, something that really improves performance during those tricky transitions between different types of underground formations.

Shearing Action of PDC Bits: The Role of Polycrystalline Diamond Cutters

PDC bits, also known as Polycrystalline Diamond Compacts, work with fixed cutters covered in synthetic diamonds that cut through rock by continuous shearing action. They're different from tricone bits because there are absolutely no moving parts involved. Instead, these tools use blade-like cutter setups that effectively scrape through formations when spinning at high RPMs. The diamond coated cutters stay sharp anywhere from 50 to even 100 times longer than regular materials when working in softer to medium hardness rocks. This helps reduce both friction and heat generation during drilling operations. As for performance metrics, field tests show that this shearing mechanism can boost rate of penetration (ROP) by roughly 2 to 4 times in consistent rock types such as shale deposits or salt formations compared with traditional rolling cone bit technology. For drillers looking to maximize footage per bit run, this makes a real difference in operational efficiency.

Key Structural Differences: Bearings, Cutter Layout, and Bit Profiles

| Feature | Tricone Bits | PDC Bits |

|---|---|---|

| Moving Parts | Bearings, seals, rotating cones | Fixed cutters, no bearings |

| Cutter Arrangement | Staggered teeth/inserts on cones | Spiral/radial blades with 6–8 cutters |

| Bit Profile | Rounded for impact absorption | Flat/conical for optimized shearing |

Tricone designs emphasize mechanical durability with sealed roller bearings that withstand vibration in hard rock, while PDC bits enhance fluid flow and cuttings evacuation through open-face profiles.

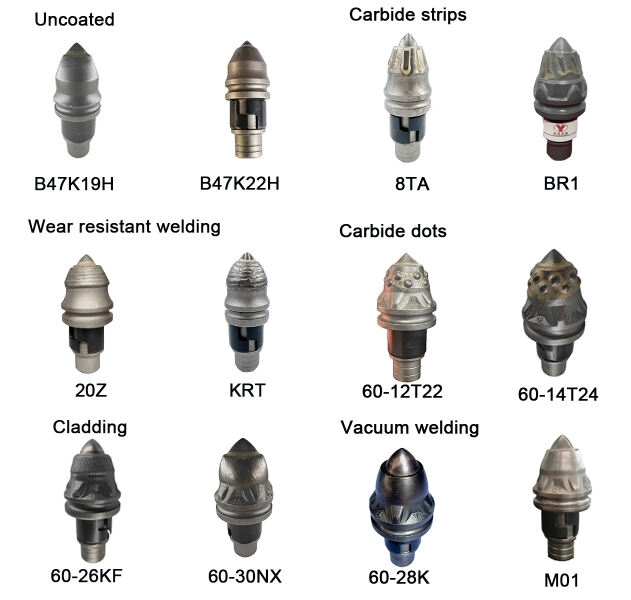

Cutter Size and Configuration: Matching Cutting Structure to Formation Hardness

When working with softer rock formations, larger PDC cutters measuring between 13 to 19 millimeters work best because they provide greater shear area which boosts rate of penetration. For tougher, abrasive areas though, smaller cutters ranging from 8 to 12 mm with stronger substrate backing tend to last longer on the drill bit. Tricone bits handle different formation hardness through their tooth configuration. In softer ground conditions, we typically see longer spaced teeth, whereas in harder or fractured rock formations, the teeth are shorter and packed closer together. Some newer hybrid drill bit designs actually merge the cutting efficiency of PDC technology with the durability characteristics of traditional tricone bits. These combinations have shown real improvements when drilling through alternating layers of limestone and sandstone, which presents quite a challenge for conventional equipment.

Performance in Different Geological Formations: Where Each Bit Excels

Soft Formations: High ROP with PDC Bits

PDC bits dominate in soft formations like clay and unconsolidated sands, where their shearing action achieves ROP up to three times faster than tricone bits. The polycrystalline diamond cutters efficiently slice through pliable rock without excessive heat generation—critical when drilling water-sensitive shales or gumbo layers.

Medium to Hard Rock: Tricone’s Superior Tolerance and Stability

Tricone bits really shine when drilling through those medium hard formations like limestone and dolomite, especially where there's need for good impact resistance. What makes them work so well is that rolling cone design which spreads out the mechanical stress across all those bearings. This helps keep the rate of penetration pretty steady around 4 to 6 meters per hour even when running into those annoying hard stringers that can slow things down. Field tests have actually demonstrated something interesting too: tricone bits fitted with tungsten carbide inserts tend to drill about 12 to 15 percent faster compared to regular PDC bits under similar formation conditions. Makes sense why many operators still prefer them for certain applications despite newer technologies on the market.

Mixed and Abrasive Zones: Challenges for PDC Cutters

PDC bits’ shearing efficiency becomes a disadvantage in interbedded sequences with chert nodules or quartzite layers. Abrasive materials increase cutter wear by 20–30% compared to tricone bits’ grinding mechanism, as demonstrated in a 2023 analysis of Permian Basin drilling operations.

Case Study: Drilling Efficiency in the Texas Eagle Ford Shale

Field tests conducted in 2023 across the Eagle Ford shale formations showed just how much better PDC bits perform compared to traditional alternatives. During these trials, drillers managed to reach speeds around 28.5 meters per hour thanks to specially arranged cutters on the bit face. What really made a difference though were the new methods for controlling vibrations downhole. These techniques cut down on early wear issues by roughly 40%, which means less downtime and fewer replacement costs. When companies combine smart bit designs with careful adjustments during actual operations, they're seeing real improvements in their bottom line. The results from Eagle Ford suggest that PDC technology isn't just promising it's already delivering tangible benefits for operators willing to invest in good engineering practices.

Formation Suitability and Drill Bit Selection Based on Lithology

Carbonates vs. Interbedded Formations: Matching Bits to Rock Type

PDC bits work best in uniform carbonate rock because they cut efficiently across consistent rock structures. On the flip side, tricone bits equipped with tungsten carbide inserts (TCI) perform much better when dealing with mixed layers of shale, sandstone, and clay. Their crushing action is just what's needed for these kinds of formations where hardness changes suddenly from one layer to another. A recent drilling project in Northern Iraq back in 2024 showed that PDC bits managed to drill through limestone at 18% faster rate compared to other methods. Meanwhile, those same TCI bits cut down on problems caused by vibrations by around 32% when working through alternating rock types. Matching the right bit to the specific rock type makes a real difference economically too. Drilling costs drop by about 22 cents per meter when there are fewer times spent changing bits and the overall drilling speed improves.

Rock Hardness Classification and Decision Framework for Bit Choice

A systematic rock hardness framework guides bit selection:

| Formation Hardness | Recommended Bit Type | Key Advantages |

|---|---|---|

| Soft (UCS < 10k psi) | PDC or milled-tooth tricone | High ROP, efficient cutting |

| Medium (10-20k psi) | Hybrid PDC/TCI configurations | Balanced durability & speed |

| Hard (>20k psi) | Dense TCI tricone | Impact resistance, stability |

The IADC classification system supplements this by quantifying abrasiveness and compressive strength, enabling drillers to align bit specifications with formation challenges. For example, TCI bits with IADC code 415 withstand quartz-rich zones where PDC cutters suffer thermal damage.

Optimal Use Cases: When to Choose PDC vs. Tricone Based on Conditions

Select PDC bits for vertical wells in uniform carbonates or soft shales requiring maximum ROP. Opt for tricone bits when drilling:

- Directional wells through faulted zones

- Highly abrasive formations (e.g., sandstone with >40% quartz content)

- Intervals with unpredictable lithology changes

Tricones' mechanical bearings tolerate sudden hardness spikes better than PDC's fixed cutters, reducing catastrophic failure risks by 27% in complex basins according to dull bit analysis.

Cost Efficiency and Total Cost of Ownership: PDC vs. Tricone Bits

Upfront Costs: Why PDC Bits Require Higher Initial Investment

PDC drill bits incur 40–60% higher initial costs than tricone bits due to complex manufacturing of synthetic diamond cutters and specialized materials. This premium reflects advanced engineering but creates a barrier for capital-constrained operations. Conversely, tricone bits offer immediate budget relief through simpler construction and readily available tungsten carbide inserts.

Cost Per Meter Analysis: Long-Term Savings with PDC in Suitable Formations

Drilling through those soft to medium rock layers such as shale or limestone? PDC bits actually pay off in the long run even though they cost more initially. The way these bits cut through the formation gives operators around 30 to 50 percent better penetration rates. Plus, workers don't have to replace them nearly as often as traditional tricone bits either. Some field tests show that this can cut down on costs by roughly 18 to 25 cents per meter drilled when working with consistent rock types. Field crews who've switched over report noticeable savings after just a few wells, making the extra initial expense worth it for most operations.

Downtime, Replacement Frequency, and Maintenance Impact on TCO

Tricone bits incur hidden operational costs through:

- Bearing maintenance: Require regular lubrication with failure rates increasing by 15% in abrasive zones

- Trip time: 3–5 more bit changes per well compared to PDC bits

-

Fishing operations: Risk of cone loss costing $15k–$50k per incident

PDC bits eliminate moving parts, reducing non-productive time by 20–35% and slashing maintenance overhead.

Field Data: Cost Per Foot in North Dakota Bakken Operations

| Bit Type | Avg. Cost/Foot | Avg. Lifespan (ft) | Trips per Well |

|---|---|---|---|

| PDC | $42 | 3,800 | 1.2 |

| Tricone | $67 | 1,200 | 4.3 |

| Data aggregated from 27 Bakken shale wells (2023) | |||

| PDC bits achieved 37% lower cost/foot through extended durability in this shale formation, validating their TCO advantage despite 2.8— higher purchase price. |

Durability and Lifespan in Challenging Drilling Environments

Wear Resistance in High-Abrasion Formations

PDC bits really shine when working through those tough abrasive sandstone and shale layers because they're equipped with these special polycrystalline diamond compact cutters. These cutters just handle friction so much better compared to what we used to see with older materials. On the flip side, tricone bits depend heavily on tungsten carbide inserts, but these tend to wear down pretty quickly when exposed to rocks rich in silica over extended periods. According to field tests conducted across various drilling sites, most PDC cutters still maintain around 80 to 90 percent of their original cutting power even after clocking in about 150 hours in harsh formations. Meanwhile, operators usually find themselves needing to replace tricone parts somewhere between 50 and 70 hours later under comparable conditions. This difference makes a big impact on operational costs and downtime for drilling operations.

Thermal and Mechanical Degradation: PDC Cutters vs. Tungsten Carbide Inserts

The intense heat found deep underground over 300 degrees Fahrenheit or around 149 Celsius impacts different drill bits in their own ways. PDC cutters stay intact until they hit about 1,292 Fahrenheit because diamonds conduct heat so well, though sudden temperature changes might crack them at microscopic levels. When it comes to tricone bits, the real problem is what happens to their bearings when things get hot. Sealed roller bearings just don't work as well anymore, losing roughly a third of their lubrication effectiveness for every 50 degree increase in temperature. Tungsten carbide inserts tend to chip away slowly instead of breaking all at once, which actually makes them pretty reliable in areas where temperatures fluctuate constantly. Most field engineers prefer this predictability when working in these challenging conditions.

Balancing High ROP and Bit Survivability in Variable Zones

Field operators tend to go with PDC bits when they need those high rate of penetration numbers in consistent rock formations, though they'll typically swap out for tricones once they hit those tricky layers of limestone mixed with chert. A recent field test down in the Permian Basin back in 2023 showed some interesting results too. The PDC bits were knocking out around 22% better ROP than their tricone counterparts, no doubt about it. But here's the catch - whenever there was sudden shifts in rock hardness, crews ended up making roughly three times as many trips to change bits. That's where smart drilling teams start thinking about hybrid approaches. Using tricones through those transition zones while saving PDCs for the solid sections actually cut overall drilling expenses by about eighteen bucks fifty cents per foot versus sticking with just one type of bit throughout. Makes sense when you think about it from both the wallet and efficiency standpoint.

FAQ

What are the main differences between Tricone and PDC drill bits?

Tricone bits use rotating cones and are ideal for mixed ground conditions while PDC bits feature fixed cutters covered in synthetic diamonds and excel in consistent rock formations.

Why are PDC bits more expensive initially?

PDC bits involve complex manufacturing due to synthetic diamond cutters, explaining their higher upfront costs compared to simpler tricone constructions.

How do Tricone bits handle different geological formations?

Tricone bits are adaptable, using tooth configurations to handle soft and hard formations. They excel in medium-hard formations like limestone and dolomite.

When is it best to choose PDC bits over Tricone bits?

Choose PDC bits for vertical wells in uniform carbonates or soft shales where high rate of penetration is required.

How do the costs per meter compare between PDC and Tricone bits?

PDC bits tend to offer long-term savings in suitable formations, reducing costs by 18-25 cents per meter due to higher durability and penetration rates.

Table of Contents

- Cutting Mechanisms and Structural Design: How Tricone and PDC Drill Bits Work

- Performance in Different Geological Formations: Where Each Bit Excels

- Formation Suitability and Drill Bit Selection Based on Lithology

- Cost Efficiency and Total Cost of Ownership: PDC vs. Tricone Bits

- Durability and Lifespan in Challenging Drilling Environments

- FAQ