Understanding Tricone Drill Bits: Design, Components, and Working Principles

What are tricone bits and their role in modern drilling operations?

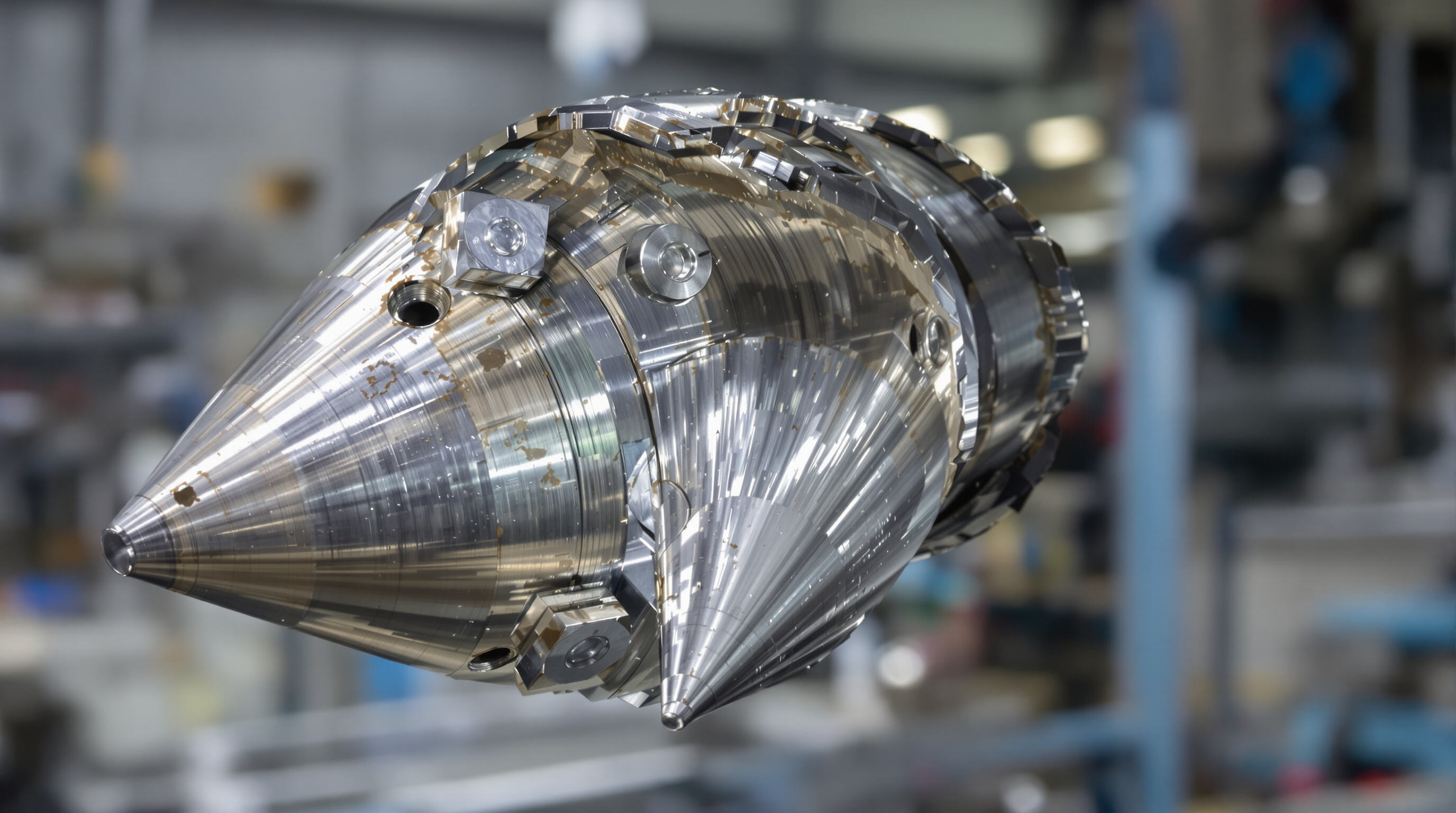

Tricone bits are basically rotary drill bits with three cone-shaped rollers that spin on their own while working. What makes these special drill bits so good at getting through different types of ground is because they crush, shear, and grind all at once. Because of this versatility, companies in the oil and gas sector, miners looking for ore deposits, folks drilling water wells, and construction crews rely heavily on tricones for their jobs. Compared to those single cone bits, tricones spread out the work better across all three cones which cuts down on vibrations during drilling operations. They still manage to push through pretty much anything from loose soil down to solid granite without slowing down too much. The real advantage becomes apparent when drilling conditions get tough - most other bit types either stop working altogether or need replacing way too often under similar circumstances.

Anatomy of a tricone bit: Key components and structural design

A tricone bit's effectiveness stems from its precisely engineered components:

- Cones: Three rotating structures with cutting elements (teeth or inserts) that fracture rock

- Legs: Steel arms connecting cones to the bit body, housing bearing systems

- Bearings: Facilitate cone rotation under extreme loads

- Nozzles: Direct drilling fluid to remove cuttings and cool components

- Gauge protection: Hardfacing materials preventing outer edge erosion

The structural design features intermeshing cones with calculated offsets to maximize rock fragmentation while maintaining borehole diameter accuracy. Advanced metallurgy in legs and cones withstands downhole stresses exceeding 20,000 PSI.

How tricone bits work: Rotational shearing and compression mechanics

Tricone bits work using two main ways to break rocks apart. When the drill string spins, the cones on the bit move along the rock face, applying pressure that actually causes the rock to crack from tension rather than just being crushed. At the same time, the way these cones are positioned creates another effect where the teeth literally scrape and dig into the rock layers. This mix of breaking methods works really well on formations that would normally stand up to either pure crushing or regular cutting techniques alone. What's interesting is how each cone can rotate separately, which helps them adjust when running into rough spots in the rock. Meanwhile, special fluids get pumped down through nozzles in the bit to wash away all the broken rock pieces, keeping things moving smoothly as the drill goes deeper into the ground.

Sealed vs open bearing systems and hydraulic efficiency through nozzle design

Bearing systems critically impact tricone bit longevity and application suitability:

| System Type | Operating Environment | Average Lifespan | Maintenance Needs |

|---|---|---|---|

| Sealed | Abrasive/harsh | 120–150 hours | Minimal |

| Open | Clean/less demanding | 60–80 hours | Frequent lubrication |

Sealed bearings have several barriers that keep out dirt and debris, making them really good for those rough, gritty environments. On the flip side, open bearings save money when there's no corrosion risk around, though they need constant checking and upkeep. When it comes to hydraulic systems, how the nozzles are set up makes all the difference. Getting the right flow rate and positioning those jets properly can make a big impact on clearing away cuttings from drilling operations, plus helps avoid that annoying balling effect. Choosing the correct nozzles matters because stagnant fluids just sit there and eat away at bits faster than anyone wants. Most field engineers know this from experience after seeing too many expensive replacements downhole.

Tricone Bit Types: Comparing MT, TCI, and Hybrid Designs for Optimal Performance

Milled Tooth (MT) vs Tungsten Carbide Insert (TCI) Tricone Bits: Core Differences in Cutting Structure

MT bits feature steel teeth milled directly onto cones, optimized for rapid penetration in soft-to-medium formations like shale and sandstone. TCI bits use tungsten carbide inserts brazed into cones, delivering 30–50% longer lifespan in hard, compact strata like granite. Key differences:

- Cutting Mechanism: MT teeth scrape and gouge, TCI inserts fracture through compression

- Durability: TCI withstands 2–3x higher formation hardness (Mohs scale 5–8)

- Cost Profile: MT averages $800–$1,200 vs TCI’s $2,500–$4,000 range

TCI Bits in Hard Formations: Superior Wear Resistance and Longevity

TCI’s tungsten carbide composition (90% WC, 10% cobalt binder) resists abrasive wear 60% better than steel in quartzite. A 2024 IADC study showed TCI bits drilled 420 meters in basalt vs MT’s 140 meters before replacement in identical conditions.

MT Bits for Soft, Abrasive Formations: High Rate of Penetration and Efficiency

In unconsolidated sandstone, MT bits achieve 12–18 m/hr penetration rates—2x faster than TCI. Their open-tooth design clears cuttings 35% more effectively in water-saturated clays, reducing balling risks.

Hybrid and Fixed-Cutter Innovations: Expanding Tricone Bit Capabilities

Leading manufacturers now combine MT’s cutting aggression with TCI’s durability in hybrid designs. Recent field tests in interbedded limestone/shale showed hybrids outlasted standard bits by 22% while maintaining 15 m/hr ROP. Fixed-cutter variants with PDC elements are solving historically unstable drilling in fractured coal measures.

Matching Tricone Bits to Geological Conditions Using IADC Standards

Classifying rock types by hardness and abrasiveness for accurate bit selection

Choosing the right tricone bit really starts by looking at what kind of rock or soil we're dealing with down there. The IADC has this system where they sort different types of ground into eight categories based on how hard they are to drill through and how much they wear down equipment. At one end we have soft stuff like clay which is easy going but not so tough on bits (Classes 1 and 2), while at the other extreme there's those super hard rocks like granite that fall under Class 8. Take sandstone for instance. Most often it lands somewhere between Classes 4 and 5 because although it isn't the hardest material around, it does tend to be pretty abrasive. That means operators need bits that can cut efficiently without getting worn out too quickly when working with these kinds of formations.

IADC coding system: Decoding tricone bit classifications for formation matching

The IADC’s four-digit code simplifies bit-to-formation matching:

- First digit: Bit type (1–3 for milled tooth, 4–8 for tungsten carbide inserts)

- Second digit: Formation hardness (1=softest, 8=hardest)

- Third/Fourth digits: Secondary features like bearing type or seal design

A TCI bit coded IADC 537 indicates suitability for medium-hard formations (second digit “3”) with sealed roller bearings (third digit “7”), making it ideal for abrasive sandstone layers.

Case Study: Selecting the right tricone bit for mixed carbonate-sandstone formations

In early 2023, a drilling operation running in the Permian Basin hit some serious trouble with their bits wearing out way too fast – around 47% degradation after just 60 hours of work in those tricky alternating limestone and sandstone formations. When they made the switch from their standard MT bit (IADC code 127) over to this newer hybrid TCI model (IADC 437), things changed dramatically. The new setup kept going strong for 82 straight hours, cutting down the cost per foot by nearly 30%. What really impressed the crew was how this upgraded bit handled both rock types better. It cut through the tough sandstone sections without all that annoying cone slippage, yet still maintained good progress rates when moving into the softer limestone layers where most bits tend to slow down.

Applications Across Industries: Oil & Gas, Mining, Water Well, and Construction

Tricone Bits in Oil & Gas Drilling: Performance in Deep, High-Pressure Environments

Tricone drill bits perform really well in the tough world of oil and gas drilling when conditions get rough and equipment needs to hold up. These bits have sealed bearings and tungsten carbide inserts that can handle immense pressure down in those deep wellbores. The pressure? Sometimes over 15 thousand pounds per square inch! And let's not forget about their nozzle design either. Engineers have worked on making these nozzles better so the hydraulic system works more efficiently when drilling at angles. Some recent research from 2025 looked at how offshore drilling systems work, and what did they find? Tricone bits stand up pretty good against corrosion underwater. In fact, they drill through sedimentary rock layers about 20 to maybe even 30 percent faster than those old school fixed cutter bits we used to rely on back in the day.

Mining and Water Well Applications: Penetrating Variable Strata Efficiently

Tricone bits work really well in both mining operations and water well drilling when dealing with all sorts of changing rock layers underground. The three cones on these bits help prevent what's called bit balling when going through clayey ground, yet they stay stable enough even when hitting broken up bedrock areas. Because of this flexibility, drillers can change out tools less often than with older single cone designs. Some field reports show around a 40 to 50 percent drop in tool changes for projects like mineral exploration shafts or deep water wells over 500 meters long that pass through alternating sandstone and granite layers.

Construction Drilling: Adaptability in Urban and Rugged Site Conditions

Tricone bits have become a real game changer for construction work where space is tight and precision matters. The smaller size lets crews drill foundations even on those tiny 2 meter plots common in city centers. What makes these bits stand out though are those tough milled teeth that can chew right through reinforced concrete and stubborn glacial till without breaking a sweat. Looking at recent roadwork and building projects across the country, contractors report saving about 15% compared to other drilling techniques when they use tricones for things like bridge piles and installing geothermal heating loops. Makes sense really since time spent waiting for equipment to finish means money down the drain.

Cost-Effectiveness and Future Trends in Tricone Drill Bit Technology

Total cost of ownership: Why tricone bits remain economical in 2025

Tricone drill bits might cost more upfront but save money over time because they last longer and work better overall. They cut through rock much faster than regular bits, shaving around 15 to maybe even 30 percent off drilling projects. The bits also have those tough tungsten carbide pieces that don't wear out so quickly, meaning fewer replacements needed during operations. The way these bits are designed actually cuts down on power usage by about twenty percent, which matters when running big rigs all day long. Less time waiting for repairs means smoother workflow across the site. Industry reports suggest that drilling costs per meter drop roughly 25 percent with tricones, and this trend seems likely to continue well into next year as companies keep looking for ways to cut expenses without sacrificing productivity.

Top manufacturers and innovations: Wuhan Yi Jue Tengda Machinery Co LTD and global advancements

Manufacturers across the industry are working hard to boost how well tricone bits perform, mainly by playing around with better metals and getting really good at precise manufacturing techniques. Some of the latest stuff includes mixing different types of cutting surfaces where they combine regular milled teeth with those tough carbide inserts, which works great when drilling through all sorts of rock layers. They've also developed sealed bearings that last way longer than before – maybe three times as long if conditions are right. Research teams worldwide are experimenting with bits that can actually adjust themselves based on what kind of rock they hit next. And there's some special heat treatment methods being used now that makes parts last much longer, though nobody wants to get too specific about exactly how much longer. All these improvements mean drillers can keep going strong even when things get really rough downhole.

Sustainability, automation, and AI-driven design in modern drill bit manufacturing

There's been a noticeable move in the industry towards producing goods with environmental concerns in mind. Recycled content now makes up around 30 to 50 percent of what goes into making new drill bits. These days, many drill bits come equipped with Internet of Things sensors that track performance as it happens. This gives companies advance warning when something might go wrong, which cuts down on breakdowns by about 35%. Some smart computer programs are getting pretty good at designing better drill bits too. They run simulations based on rock formations and have boosted how fast drills can penetrate ground material by roughly 22% per recent studies from 2024 on drilling gear. Factories that automate their production processes achieve tighter specifications while simultaneously reducing both power consumption and material waste by approximately 25%. All these improvements make for drilling operations that leave a smaller footprint on the environment without sacrificing quality.

FAQ

What are tricone drill bits primarily used for?

Tricone drill bits are used extensively in oil and gas drilling, mining, water well drilling, and construction due to their ability to crush, shear, and grind various ground types.

What are the key differences between MT and TCI tricone bits?

MT bits have milled steel teeth suitable for soft to medium formations, while TCI bits use tungsten carbide inserts ideal for hard formations offering longer durability.

Why are sealed bearings preferred in harsh drilling environments?

Sealed bearings protect from dirt and debris, making them suitable for abrasive conditions and reducing maintenance needs compared to open bearings.

How does the IADC coding system help in selecting the right tricone bit?

The IADC code helps by categorizing bits according to formation type and features, thereby aiding in selecting suitable bits for specific geological conditions.

Table of Contents

- Understanding Tricone Drill Bits: Design, Components, and Working Principles

-

Tricone Bit Types: Comparing MT, TCI, and Hybrid Designs for Optimal Performance

- Milled Tooth (MT) vs Tungsten Carbide Insert (TCI) Tricone Bits: Core Differences in Cutting Structure

- TCI Bits in Hard Formations: Superior Wear Resistance and Longevity

- MT Bits for Soft, Abrasive Formations: High Rate of Penetration and Efficiency

- Hybrid and Fixed-Cutter Innovations: Expanding Tricone Bit Capabilities

- Matching Tricone Bits to Geological Conditions Using IADC Standards

- Applications Across Industries: Oil & Gas, Mining, Water Well, and Construction

- Cost-Effectiveness and Future Trends in Tricone Drill Bit Technology

- FAQ