What Are Tungsten Carbide Bullet Teeth?

Composition and Manufacturing Process

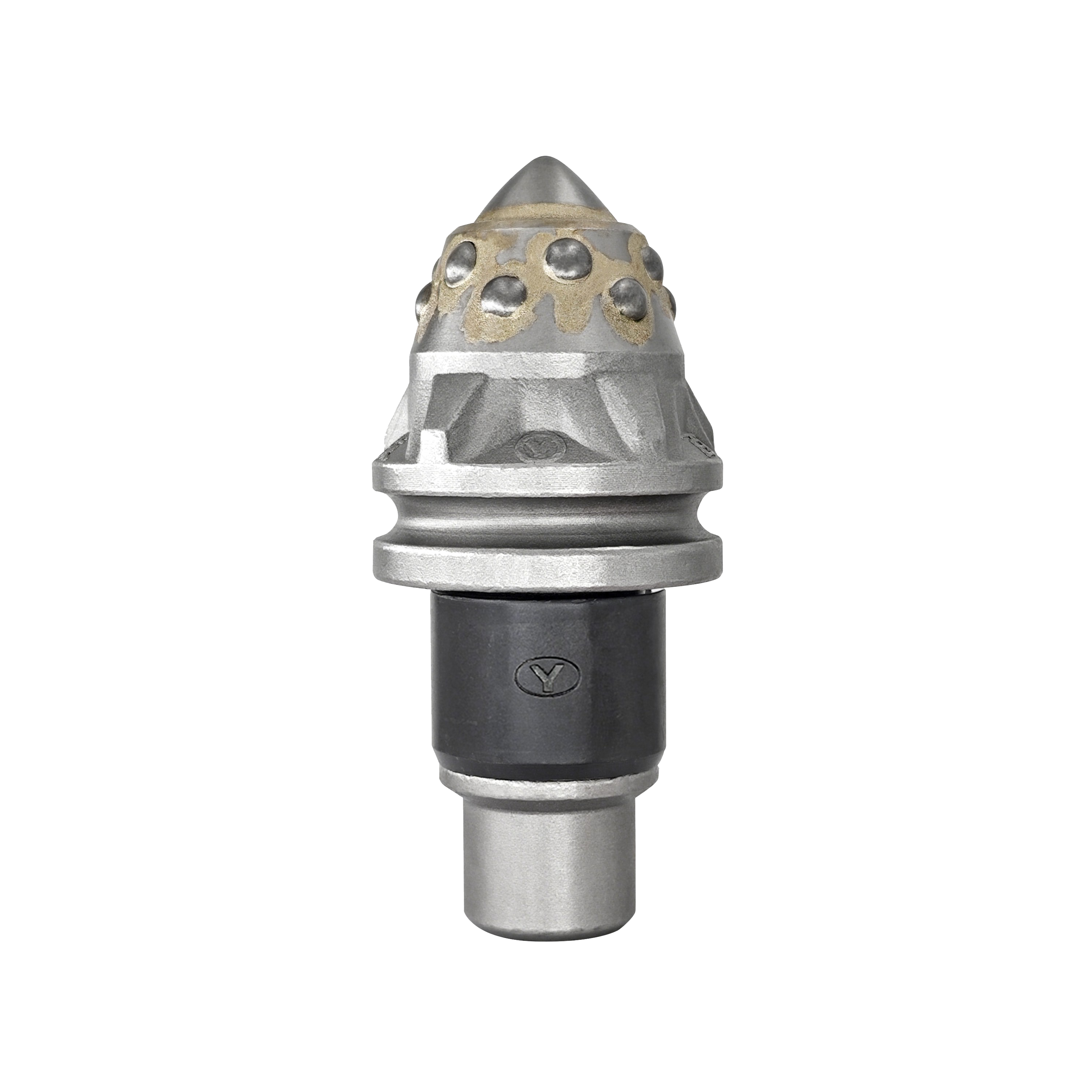

Bullet teeth made from tungsten carbide have a hardened steel base that's joined to a tungsten carbide point through a special heating process called sintering, usually done around 1,400 to 1,600 degrees Celsius. What happens during this is pretty interesting actually - the raw materials get compressed together under intense heat until they form something really tough and resistant to wearing down over time. Most of these carbide tips are composed between 85 and 95 percent actual tungsten carbide mixed with either cobalt or nickel as binding agents. The whole thing is designed so it stays super hard but still can take impacts without breaking apart when used in tough digging operations where regular tools would fail after just a few hours of work.

Key Mechanical Properties (Hardness, Wear Resistance, Impact Toughness)

These teeth deliver a critical combination of mechanical performance:

- Hardness: Exceeds Rockwell C 90 (or 90 HRA), enabling reliable penetration of granite, reinforced concrete, and other high-abrasion materials

- Wear resistance: Outperforms standard tool steel by 8–10— under abrasive conditions, as validated in peer-reviewed field testing (Mining Tech Journal, 2025)

- Impact toughness: Withstands over 50 Joules of impact energy without fracturing—key for resisting chipping during high-stress rock drilling

This balanced property profile reduces tooth replacement frequency by 30–40% in rock excavation, directly lowering operational downtime and maintenance costs.

Primary Applications of Tungsten Carbide Bullet Teeth

Tungsten carbide bullet teeth are purpose-built for environments where abrasion, impact, and mixed-ground conditions rapidly degrade conventional cutting tools. Their exceptional hardness and fracture resistance make them indispensable across heavy civil infrastructure and mineral extraction operations.

Rock Excavation and Mining Equipment

These specialized cutting tools are attached to excavation drums and continuous miners where they break apart tough rock formations. They hold up well against the grinding effects of quartz rich deposits that would normally wear down regular equipment. The special material gives them extra strength so they don't chip when subjected to constant hammering forces. This durability means machines last about 40 percent longer than those fitted with standard steel teeth. For mining operations both above ground and below, this translates into fewer replacements needed and less downtime caused by unexpected failures, which saves money and keeps production moving smoothly.

Cold Planers and Asphalt Milling Machines

On milling drums, the carbide tips maintain sharp, consistent cutting edges through aged asphalt containing abrasive aggregate like basalt and granite. This enables precise depth control and uniform surface profiling. Field data from highway rehabilitation projects show operators achieve 25% faster material removal rates while reducing mid-shift tool changes.

Trenchers and Horizontal Directional Drilling (HDD) Tools

In trenching and HDD applications, the streamlined bullet geometry minimizes drag when penetrating variable substrates—from clay and sand to fractured bedrock. This improves steering accuracy and power transmission efficiency during utility installation. Independent field studies report a 30% increase in linear footage drilled before replacement versus standard carbide cutters.

| Application | Key Benefit | Performance Gain |

|---|---|---|

| Mining | Wear resistance in abrasive rock | 40% longer lifespan |

| Asphalt milling | Consistent cutting precision | 25% faster removal |

| HDD/Trenching | Reduced drag in varied soils | 30% increased footage |

How to Select the Right Tungsten Carbide Bullet Teeth for Your Equipment

Matching Tooth Geometry to Ground Conditions

The shape of cutting teeth needs to match what's actually underground—not just how hard the material is, but things like grain size, how wet it gets, and layers within the soil. Teeth shaped like cones or chisels really pack a punch when breaking through tough rock or ice. Flat or rounded teeth spread out the pressure better in gritty soils such as sand and gravel, which helps keep the edges from wearing down so fast. When picking the right tooth design, checking soil types using ASTM D2487 guidelines and looking at Standard Penetration Test results makes sense. Getting this wrong can lead to tools wearing out much quicker, sometimes up to 40% faster based on field tests over many months of actual drilling operations.

| Terrain Type | Recommended Geometry | Performance Benefit |

|---|---|---|

| Solid Rock/Concrete | Sharp Conical | High point loading for fracture |

| Mixed Abrasive Soils | Rounded Flat | Reduced wear, consistent material flow |

| Frozen Ground | Reinforced Chisel | Impact resistance, crack propagation |

Compatibility with Cutting Drum or Tool Holder Specifications

Physical compatibility is non-negotiable. Verify shank diameter, retention mechanism (e.g., pin-lock, clip-secured), and mounting angle against your equipment's OEM specifications. Incompatible teeth risk:

- Vibration-induced fatigue damage to drum welds and bearings

- Sudden ejection under high-torque loads—posing safety hazards

- Power transfer inefficiency, reducing effective cutting force

Always cross-reference manufacturer documentation for holder tolerances. While ISO-compliant standardized teeth offer broad interchangeability and faster logistics, legacy or custom machinery may require OEM-certified or engineered solutions. Prioritizing certified dimensions safeguards warranty coverage, operational reliability, and worksite safety.

Maintenance, Lifespan, and Cost Efficiency of Tungsten Carbide Bullet Teeth

Bullet teeth made from tungsten carbide tend to outlast regular steel ones by about three times when working with abrasive materials. This means operators need to replace them less often, spend less time waiting for repairs, and ultimately save money over time. Keeping these teeth performing at their best requires some smart maintenance practices. Check them visually both before starting work and after finishing each shift looking for signs like cracks, chips, or worn down tips. Get rid of any built up debris right after operations while it's still fresh to stop corrosion problems from developing. Don't forget to put on the lubricant recommended by the manufacturer where the tool meets the shank area. This helps prevent that annoying fretting wear that can really cut short the life of expensive equipment.

The upfront price might be steeper, but when we look at how long these parts last plus the savings from better maintenance practices, the return on investment becomes pretty attractive. According to industry data, companies that stick to regular checks and thorough cleaning routines often see their cutting teeth last around 30% longer during those intense digging operations. When every minute counts for projects running against tight deadlines and profit margins, investing in tungsten carbide bullet teeth makes real sense. These teeth have stood the test of time across countless job sites, backed by solid engineering principles and years of actual field testing. Most operators will tell anyone who asks that this upgrade pays off in the long run.

FAQ Section

Tungsten carbide bullet teeth are superior due to their exceptional hardness, wear resistance, and impact toughness, which extend lifespan and reduce downtime in abrasive conditions.

These teeth are primarily used in rock excavation, mining equipment, cold planers, asphalt milling machines, trenchers, and HDD tools.

Select teeth based on matching geometry to ground conditions and ensuring compatibility with equipment specifications.

Regular visual inspections, cleaning after operations, and proper lubrication to prevent wear and corrosion are recommended.