Understanding Kelly Bars: Function and Core Design in Drilling Systems

What Is a Kelly Bar in Rotary Drilling Systems?

The kelly bar serves as the main link for transferring torque in rotary drilling rigs, basically connecting the rotating mechanism to various drilling equipment like augers and casing systems. Made from telescopic steel, these bars have several interlocked parts that can stretch out to get down to the desired depth all while holding together even when subjected to massive forces. When it comes to getting rotational power from where the rig gets its energy to the actual drill bit, this component makes accurate digging possible for things like building foundations, creating diaphragm walls, and boring piles into the ground. The fact that they come in segments means operators can keep drilling continuously without having to stop and move the whole setup around. According to some field reports, this design cuts down on waiting time by roughly 40 percent when compared with older fixed length options, which explains why many contractors prefer them nowadays.

Key Features of Kelly Bars That Enable Efficient Power Transmission

Four engineering characteristics define high-performance kelly bars:

- Drive stub: Forged steel upper section that locks into the rotary drive, ensuring slip-free torque transfer

- Interlocking flanges: Precision-machined joints that prevent separation during reverse rotation

- Wall thickness grading: Tapered tube walls (14-22 mm) optimized for strength-to-weight efficiency

- Chromium plating: Reduces friction between sliding segments by 60% (Tribology International, 2022)

These features ensure reliable power delivery in challenging formations like dense gravel or fractured rock, where torque demands exceed 18,000 Nm.

The Role of Kelly Bars in Driving Auger Heads and Casing Tools

Kelly bars work alongside auger heads to turn rotation into actual cutting power while keeping the drill string stable during sideways movement. This stability is really important when trying to keep boreholes straight within those tight 1:200 tolerance requirements. For advancing casings through tricky ground conditions, these bars apply between 50 and 120 kilonewtons of force to push temporary casings into soft sandy soils that hold water, stopping them from collapsing altogether. The fact that they can do both cutting and stabilization at once explains why construction crews rely so heavily on kelly bars for city building projects where getting accurate holes and maintaining solid ground support matters equally.

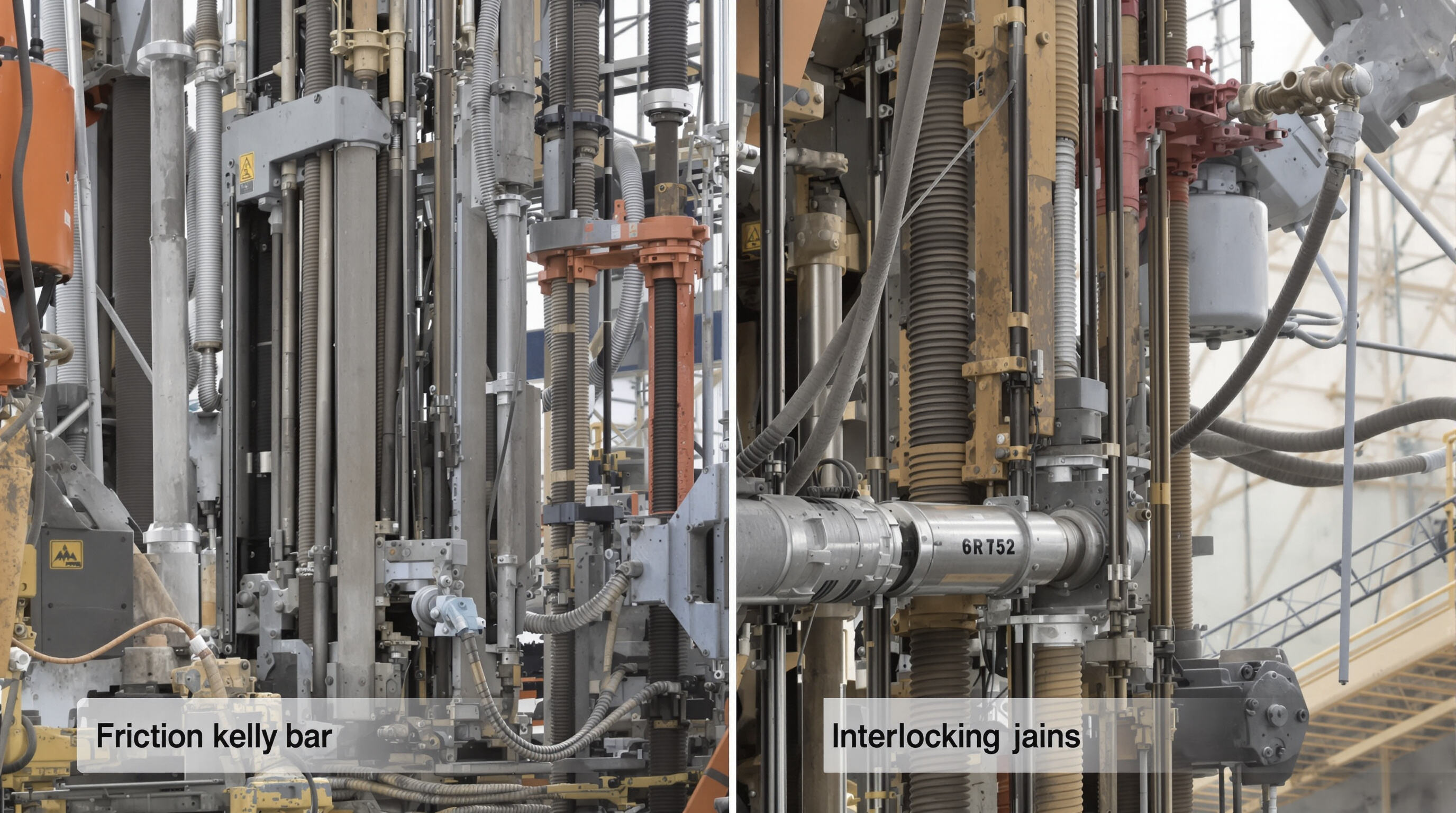

Friction Kelly Bars vs. Interlocking Kelly Bars: Performance and Structural Differences

How Friction Kelly Bars Work Through Telescopic Overlap

Friction Kelly Bars work by transferring torque through these overlapping telescoping parts that actually grip because of the pressure created between inner and outer rails. What makes them special is how they can extend step by step when working in softer ground conditions. The friction method really shines here since it gets rotational power delivered effectively without wasting energy. As for the telescopic part itself, it adjusts nicely to different digging depths while keeping everything lined up properly thanks to just right amount of friction control. No need for those complicated mechanical locks that tend to break down over time anyway.

Applications of Friction Kelly Bars in Soft to Medium Soil Conditions

The bars work best in clay and silt soils where friction helps transfer torque without losing much energy. Being lighter and easier to put together means lower costs for city pile driving jobs and shallow foundations. According to some tests published last year in the Geotechnical Engineering Journal, these friction based systems can actually penetrate sandy clay about 25% quicker than other methods. Still, they aren't so rigid that they handle hard rock formations or packed gravel very well, which limits their application in certain ground conditions.

Mechanism and Advantages of Interlocking Kelly Bar Joints

Kelly bars that interlock employ mechanical keys to secure neighboring segments so they rotate together, getting rid of those annoying slip problems we see with friction-based systems. What this means in practice is much better torque transmission capabilities reaching as high as 280 kilonewton meters. That's actually about 63 percent better performance compared to regular friction models according to research from the Deep Foundation Institute back in 2023. Another benefit comes from the solid connection between parts resisting sideways movement. This matters a lot when working in tricky soil conditions where keeping things straight vertically can be really challenging.

Superior Torque Resistance and Reduced Buckling in Interlocking Designs

Engineered for high-stress environments, interlocking bars exhibit 42% less sectional buckling under 900 kN axial loads. Their ribbed external surfaces distribute stress evenly, supporting sustained operation in fractured rock or boulder-rich strata. A 2023 geotechnical case study found interlocking systems reduced downtime by 19% in limestone formations compared to friction models.

Comparative Analysis: Friction vs. Interlocking Kelly Bars in Real-World Use

| Factor | Friction Kelly Bars | Interlocking Kelly Bars |

|---|---|---|

| Optimal Soil Type | Soft to medium (<50 MPa) | Medium to hard (>50 MPa) |

| Max Torque Capacity | 180 kNm | 320 kNm |

| Drill Precision | ±50 mm | ±15 mm |

| Project Cost | $12k–$18k per project | $22k–$30k per project |

Field data from 57 infrastructure projects show interlocking bars complete deep foundation tasks 28% faster in mixed geology, while friction models remain cost-effective for short-span bridges and residential pilings. Contractors favor interlocking systems for high-risk sites requiring ISO 22477-2 compliance.

Telescopic and Full Lock Kelly Bars: Optimizing Depth and Torque for Tough Formations

How Telescopic Kelly Bars Extend Drilling Reach in Variable Ground Conditions

Telescopic Kelly Bars feature nested steel tubes that extend using hydraulic power, making it possible to adjust depths by about 40% without having to take anything apart. According to NASD research from 2022, these bars penetrate layered soils roughly 50% better than traditional fixed-length models. The segmented design really shines when working through tricky ground conditions like switching between clay and gravel layers. Plus, they work well even in super tight spaces where radius requirements drop below 25 centimeters, something that's becoming increasingly important for urban construction projects.

Full Lock Kelly Bars and Their Role in High-Torque Rock Drilling

The Full Lock Kelly Bar system locks together all the telescoping parts at once, creating one solid torque column that can handle torsion forces as high as 380 kN·m. This kind of strength is really important when drilling through tough materials like granite and basalt formations. According to field tests conducted by ACOE last year, these bars cut down on drill string wobble by around 62% when working in metamorphic rock layers, which means straighter holes and fewer corrections needed during drilling operations. The design works better than traditional methods too. With fully engaged splines throughout the system, there's much less energy wasted. Real world measurements show about 92% torque transfer efficiency compared to only 78% from older friction based telescopic systems. That makes a big difference over long drilling runs where every bit of power counts.

Kelly Bars with Rock Auger Compatibility: Demands on Structural Rigidity

| Design Feature | Standard Kelly Bar | Rock-Auger-Optimized Bar |

|---|---|---|

| Wall Thickness | 18–22 mm | 28–32 mm |

| Flange Reinforcement | None | 360° Continuous Welding |

| Max Allowable Deflection | 1.2° | 0.4° |

| Source: Global Foundation Equipment Council, 2023 |

Rock auger compatibility requires yield strengths exceeding 550 MPa to manage asymmetric loads from stratified rock. A 2023 Canadian mining project demonstrated 34% faster penetration rates using reinforced bars with tungsten-carbide wear plates in shale-heavy formations.

Trend Analysis: Rising Adoption of Full Lock Systems in Mountainous and Hard Rock Regions

Full Lock Kelly Bar deployments grew 40% YoY in 2023 across the Andes and Himalayan ranges (USGS Mining Atlas). Contractors value their dual-phase engagement mechanism, which provides:

- 29% higher torque retention at depths over 30 meters

- 57% fewer joint inspections compared to telescopic models

- Compatibility with 800–1,200 mm diameter rock augers

This growth aligns with infrastructure projects requiring <2 mm borehole tolerance in earthquake-prone zones, where bar rigidity directly impacts foundation durability.

Specialized Kelly Bars for Unique Drilling Challenges and Site Constraints

Casing Kelly Bars for Ground Stabilization in Loose or Water-Bearing Soils

Casing Kelly bars help stabilize areas where soil tends to collapse or gets waterlogged. What makes them special is their hollow construction which allows for both drilling and installing casing at the same time something really important when working with loose gravel or wet sand layers. According to research published last year, using these systems cuts down on ground shifting by about 40 percent compared to traditional open hole techniques. This means engineers can keep things from collapsing during operations while still getting accurate results even in tricky underground environments where water content varies greatly.

Reinforced Kelly Bars for Heavy-Duty and Deep Foundation Projects

Steel Kelly bars made from high strength materials typically have walls between 25 and 40 millimeters thick. They're built to take on serious torque and heavy axial loads when working on deep foundations. The stronger versions can actually handle over 3,500 kilonewtons of force, which makes them essential for things like building skyscrapers or installing offshore wind turbines. According to some field tests across fifty different bridge construction sites mentioned in the latest Foundation Engineering Report from 2024, these reinforced bars penetrate through dense glacial till about 22 percent quicker compared to regular models. That kind of performance difference matters a lot in real world applications where time is money.

Short Kelly Bars in Confined Spaces and Low-Headroom Environments

Retrofitting cities usually means dealing with tight spaces where traditional methods just won't fit. Short Kelly bars measuring around 4 to 6 meters come into play when there's less than eight meters of headroom available. These specialized tools make all the difference for projects like expanding subways or upgrading utilities underneath buildings already standing. Take the recent metro tunnel project from 2022 as proof. The team found these shorter bars boosted drilling speed by about 30 percent in cramped working areas compared to what they could achieve with regular equipment that had been adapted for the job. For contractors stuck between old infrastructure and new requirements, this kind of efficiency matters a lot.

Integrated Kelly Bars with Auger Heads: Performance and Efficiency Metrics

The direct coupled auger Kelly system cuts down on power losses that happen through those middle connections between components, which means we're seeing anywhere from 15 to 25 percent better rotation efficiency according to last year's Drilling Mechanics Journal study. These all-in-one units really shine when working with cohesive soils, something traditional setups just struggle with because they tend to get bogged down by auger balling issues. Field tests using real time monitoring have actually shown some pretty impressive results too, with torque transfer improvements hitting as much as 28% when using specially designed auger Kelly bars instead of trying to retrofit older equipment for this application.

How to Choose the Right Kelly Bar Based on Soil Conditions and Project Requirements

Evaluating Soil Conditions and Matching Kelly Bar Selection Criteria

The type of soil we're dealing with makes all the difference when choosing the right kelly bar for the job. Friction bars really shine in softer materials like clay or sand because their telescoping design keeps transmitting power even under pressure without collapsing. When faced with tougher terrain such as compacted gravel or solid rock formations, interlocking bars become our go-to option. These provide much better structural integrity and can handle about 30 percent more stress before bending. Before diving into any drilling operation, it pays to run those soil resistivity tests first. This helps spot hidden moisture pockets and abrasive layers deep down that could chew through cheaper quality bars faster than expected, saving both time and money in the long run.

Drilling Methods and Kelly Bar Compatibility: From Soft Clay to Hard Rock

- Rotary drilling in soft clay: Use friction kelly bars with 355–500 mm diameter for optimal speed and stability

- Casing advancement in waterlogged soils: Choose full-lock systems with sealed joints to prevent fluid ingress

- Hard rock formations: Telescopic kelly bars with rock auger adapters achieve 18% faster penetration in granite (Geotechnical Equipment Journal, 2022)

Data-Driven Insights: Penetration Rate vs. Kelly Bar Type Across 50 Job Sites

A 2023 analysis of 50 foundation projects revealed:

| Kelly Bar Type | Avg. Penetration Rate (m/hr) | Optimal Soil Type |

|---|---|---|

| Friction | 4.2 | Clay, silt |

| Interlocking | 3.8 | Gravel, mixed strata |

| Full-Lock Telescopic | 5.1 | Bedrock, shale |

Projects using soil-matched kelly bars reduced drilling delays by 41% compared to mismatched configurations.

Selection Strategy Framework: Aligning Kelly Bar Type with Depth, Torque, and Site Constraints

When considering equipment needs, torque becomes critical at over 180 kN·m where interlocking bars make sense. For depths exceeding 25 meters, telescopic sections become necessary. Spatial constraints also play their part in determining what works best on site. Cities typically need shorter kelly bars that can handle about a 15 degree tilt angle, something essential when working around existing infrastructure. Mountain terrain tells a different story though. Full lock systems are practically mandatory there because they provide that extra stability needed for torque in both directions. Getting the right bar design matched to each unique job site isn't just about ticking boxes it actually makes all the difference in terms of getting the job done right the first time and ensuring foundations hold up under pressure for years to come.

Frequently Asked Questions

What is the main role of a Kelly bar in drilling systems?

A Kelly bar is critical in rotary drilling systems, transferring rotational torque to the drill bit, allowing for precision drilling necessary for foundational work such as boring piles, creating diaphragm walls, and other construction activities.

How do Friction Kelly Bars differ from Interlocking Kelly Bars?

Friction Kelly Bars transfer torque through telescopic overlap, making them ideal for soft to medium soil conditions. Interlocking Kelly Bars utilize mechanical keys for torque transmission, offering superior performance in hard soil conditions and higher torque capacity.

What are the advantages of using Full Lock Kelly Bars?

Full Lock Kelly Bars provide unmatched torque handling up to 380 kN·m crucial for drilling through hard rock formations. They minimize drill string wobble and waste less energy, achieving a higher torque transfer efficiency.

How should one choose the right Kelly bar for a project?

Choosing the appropriate Kelly bar depends on soil conditions, project requirements such as torque needs, depth, and constraints like available space. Conducting soil resistivity tests can guide selecting the suitable bar for effective and efficient drilling operations.

Table of Contents

- Understanding Kelly Bars: Function and Core Design in Drilling Systems

-

Friction Kelly Bars vs. Interlocking Kelly Bars: Performance and Structural Differences

- How Friction Kelly Bars Work Through Telescopic Overlap

- Applications of Friction Kelly Bars in Soft to Medium Soil Conditions

- Mechanism and Advantages of Interlocking Kelly Bar Joints

- Superior Torque Resistance and Reduced Buckling in Interlocking Designs

- Comparative Analysis: Friction vs. Interlocking Kelly Bars in Real-World Use

-

Telescopic and Full Lock Kelly Bars: Optimizing Depth and Torque for Tough Formations

- How Telescopic Kelly Bars Extend Drilling Reach in Variable Ground Conditions

- Full Lock Kelly Bars and Their Role in High-Torque Rock Drilling

- Kelly Bars with Rock Auger Compatibility: Demands on Structural Rigidity

- Trend Analysis: Rising Adoption of Full Lock Systems in Mountainous and Hard Rock Regions

- Specialized Kelly Bars for Unique Drilling Challenges and Site Constraints

-

How to Choose the Right Kelly Bar Based on Soil Conditions and Project Requirements

- Evaluating Soil Conditions and Matching Kelly Bar Selection Criteria

- Drilling Methods and Kelly Bar Compatibility: From Soft Clay to Hard Rock

- Data-Driven Insights: Penetration Rate vs. Kelly Bar Type Across 50 Job Sites

- Selection Strategy Framework: Aligning Kelly Bar Type with Depth, Torque, and Site Constraints

- Frequently Asked Questions