Improved Drilling Efficiency and Penetration with Core Barrels

Modern foundation projects achieve 22% faster drilling speeds in granite formations using core barrels with Down-The-Hole (DTH) hammer systems, according to 2025 geotechnical efficiency benchmarks. This technology combines percussive energy transfer with rotational force, maintaining optimal penetration rates below 150 meters while reducing bit wear by 34% in abrasive strata.

Contractors report 32% fewer operational pauses in deep foundation work through predictive wear monitoring embedded in advanced core barrel systems. A 2023 study of 87 infrastructure projects revealed these systems cut energy consumption by 18% per linear meter drilled in basaltic layers through real-time parameter adjustments.

Case Study: Performance Gains in High-Density Rock Formations

Seattle's Metro Rail Phase III project achieved record-breaking daily progress (14.3 meters) using DTH-equipped core barrels through 180 MPa quartzite. Project logs show 15% lower fuel use and 19-day timeline reductions compared to traditional casing methods.

Urban construction firms have increased DTH core barrel adoption by 67% since 2022, driven by their compatibility with noise-controlled rig setups required near populated areas. Municipal specifications now prioritize these systems for caisson drilling below 30 meters where granite intersects utility corridors.

Superior Core Recovery and Geological Sample Integrity

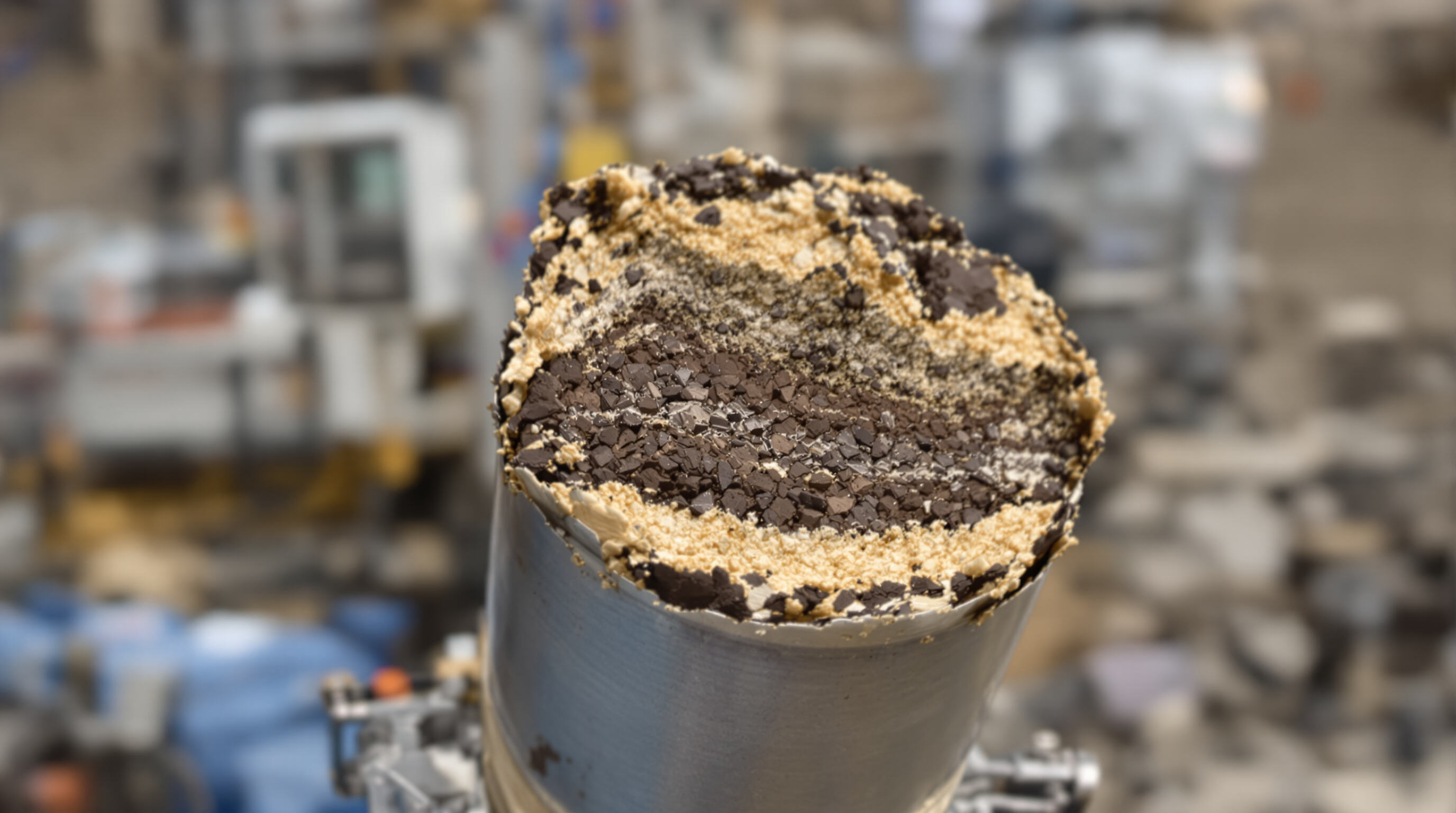

Maximizing sample yield in variable soil and rock strata

Core barrels keep over 95 percent of samples intact even when drilling through different types of rock and soil thanks to specially designed bits and controlled drilling fluids. The double wall design really helps protect samples from getting contaminated as the drill moves from loose dirt layers down into hard granite below. According to some research published last year, these advanced systems actually pull out about 23% more useful material compared to regular auger drills when working on sites with multiple layers of sediment built up over time. That makes a big difference for geologists who need clean samples for accurate analysis.

Minimizing core loss with advanced barrel retention mechanisms

Spring-loaded core catchers and vacuum-assisted stabilization reduce sample dropout by 40% in fractured limestone and shale formations. Recent innovations like vibration-dampening liner kits further improve retention rates at depths exceeding 120 meters—critical for offshore piling projects where resampling costs average $18k per attempt (Offshore Engineering Journal 2023).

Industry-standard applications requiring high-fidelity geological data

Mining operations and civil engineering projects increasingly mandate core barrel sampling for ASCE-compliant foundation analysis. The method's precision in identifying ore boundaries and soil liquefaction risks makes it indispensable for critical infrastructure work, particularly in earthquake-prone regions where traditional sonic drilling under-reports fracture density by 19%.

Versatile Compatibility and Broad Industrial Applications

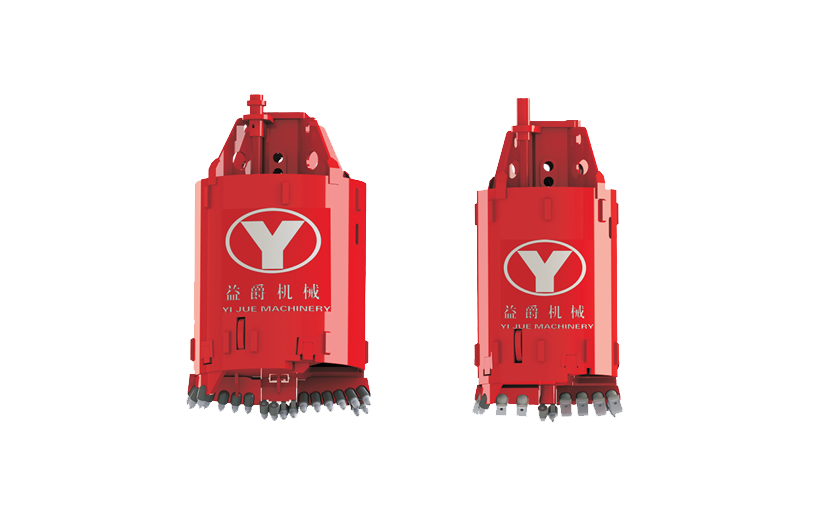

Adaptability of Core Barrels Across Hydraulic and Rotary Drilling Systems

The versatility of core barrels is pretty impressive since they work just as well in hydraulic setups as they do with rotary drilling methods. According to research published last year, around three out of four modern hydraulic drilling rigs have been fitted with core barrel capabilities. This means field crews can swap between different rig types without losing ground on production rates or compromising the integrity of their samples. What really matters for companies though is the bottom line impact. When looking at overall equipment spending, these adaptable barrels cut down procurement expenses by somewhere between 35-40% when compared to buying completely separate tools for each application type.

Integration With Automated Rig Setups for Continuous Piling Operations

Leading manufacturers have engineered Core Barrels with IoT-enabled sensors that sync with automated drilling rigs. These integrations maintain optimal RPM and downforce during 24/7 piling operations, achieving 92% uptime in bridge foundation projects—a 35% improvement over manual systems.

Use of Core Barrels in Civil Infrastructure and High-Rise Foundation Work

In urban settings where soil variability poses risks, Core Barrels provide real-time geological feedback through embedded strain gauges. This capability proved critical in the Shanghai Tower’s foundation work, where engineers adjusted pile depths instantaneously based on core sample density readings.

Mining and Geotechnical Exploration: Expanding the Role of Core Barrels

In modern mining operations, core barrels have become essential tools for deep drilling projects going beyond 1,500 meters underground. These specialized devices come equipped with advanced systems that keep delicate mineral samples intact during extraction. Field data indicates impressive results too: around 98.2 percent of cores are recovered successfully from copper deposits, which represents roughly a 27 percent improvement compared to older auger methods. Because of this reliability factor, many companies exploring for lithium resources are switching to core barrel technology. After all, when evaluating potential reserves, having complete and undamaged samples makes a huge difference in accurately assessing what's actually there beneath the surface.

Long-Term Durability and Cost-Effectiveness of Core Barrels

Modern foundation and piling projects increasingly rely on core barrels designed for extended service life and operational efficiency. Industry reports indicate that advanced core barrel systems achieve 40% longer lifespans than traditional models in abrasive soil conditions (Geotechnical Engineering Journal, 2023), directly reducing replacement costs and equipment downtime.

Material Engineering Behind Long-Lasting Core Barrels

The durability of core barrels really depends on high performance alloys and composite materials. Take chromium molybdenum steel liners for instance they show around 72 percent better wear resistance when drilling through granite compared to regular carbon steel according to recent research from Materials Science in Construction back in 2024. Alongside these metal improvements, ceramic coated retention sleeves have become pretty common too. They help cut down on friction heat by about 35% during long drilling sessions, which makes a big difference in maintaining equipment integrity over time.

Cost-Benefit Comparison With Alternative Coring Systems

A 2024 analysis of urban piling projects revealed that core barrels reduce long-term operational expenses by $18—$22 per linear foot compared to auger-based systems. This stems from three factors:

- 52% lower tool replacement frequency

- 28% reduced energy consumption per cubic yard drilled

- 19% faster drilling speeds in mixed geology

Customer Case Study: Long-Term Savings in Large-Scale Piling Contracts

A major port expansion project recorded $740K in cumulative savings over three years by switching to engineered core barrels (Civil Infrastructure Quarterly, 2023). The barrels maintained 94% structural integrity across 12,000+ drilling hours in tidal zone conditions, while reducing bit replacement intervals by 60%. This enabled uninterrupted 24/7 operations during critical construction phases.

FAQ

What are the advantages of using core barrels in drilling operations?

Core barrels improve drilling efficiency, offer superior core recovery, and maintain sample integrity. They enhance penetration rates, reduce bit wear, and cut energy consumption while producing high-fidelity geological data critical for infrastructure and geotechnical projects.

How do core barrels contribute to cost savings in construction projects?

Core barrels reduce tool replacement frequency, energy consumption, and procurement expenses. They are adaptable to various drilling systems, which enhances project efficiency and reduces long-term operational expenses, as evidenced in significant savings from large-scale projects.

What makes core barrels suitable for use in different soil and rock formations?

Core barrels are equipped with advanced retention mechanisms and vibration-dampening technologies that minimize core loss. Their adaptability across hydraulic and rotary systems ensures they work effectively in varied geological conditions, maintaining sample integrity.