Rock Auger Bullet Teeth Design: Geometry and Material Science for Hard Rock Penetration

Tungsten Carbide Bullet Teeth Geometry and Rock-Cutting Mechanics

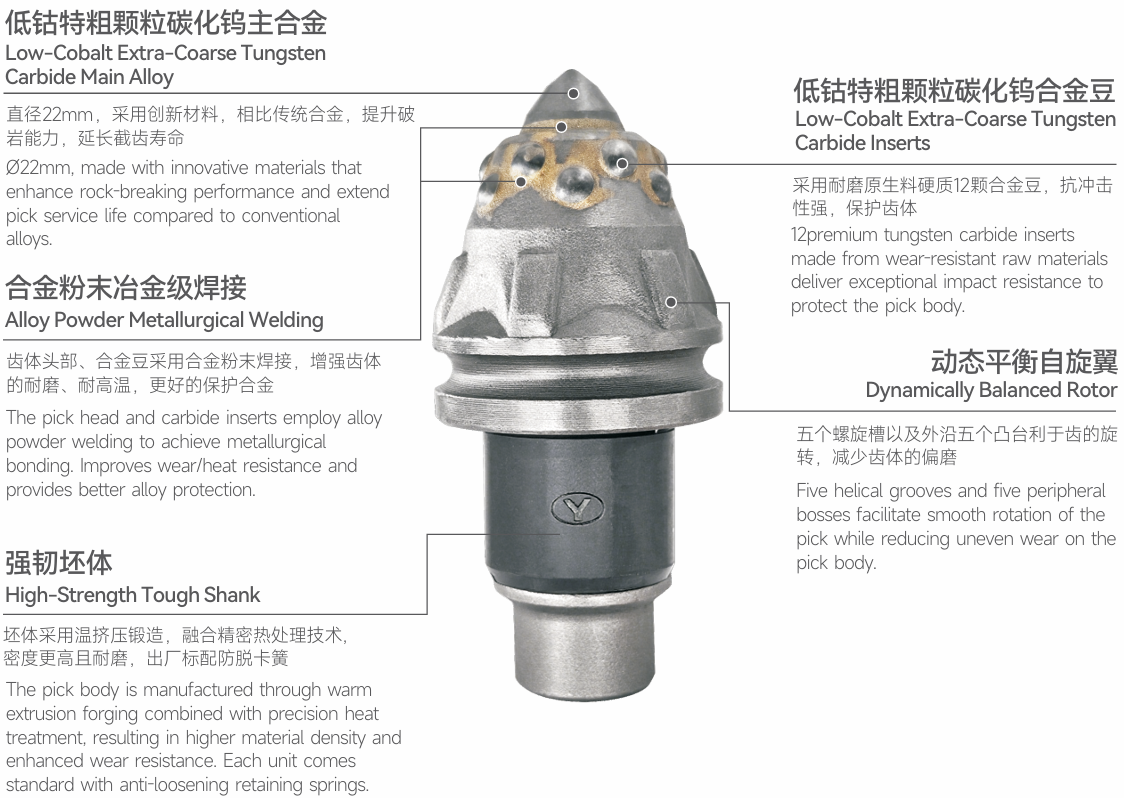

Bullet teeth on rock augers work their magic thanks to that cone shape which helps break through tough underground layers. The pointy design focuses all that drilling power into small spots, cutting down on energy needed by around 30% compared to those old flat-edged tools. When the angle at the tip gets under 60 degrees, things really start to change for the better in rocks that pack over 40 MPa compression strength. What happens here is pretty interesting actually these teeth create tiny cracks through tension instead of just smashing everything apart like regular methods do, which means cleaner chips form and there's less wasted motion. Real world testing has shown some impressive results too. Drilling operations saw their progress speed up by about 22% when switching from standard picks to these bullet tooth designs, especially noticeable in granite and basalt formations where traditional approaches struggle.

Geological Adaptation: Optimizing for >60 MPa Hard Rock Formations

For ultra-hard rock conditions exceeding 60 MPa, specialized adaptations are critical:

- Carbide grade selection: Higher cobalt binder content (8–12%) improves fracture toughness in quartz-rich formations

- Tip reinforcement: Double-layer carbide caps withstand impact stresses above 2,500 MPa

- Flank geometry: Steeper clearance angles (15–20°) prevent binding in plastic or layered rock types

- Asymmetric designs: Offset tips reduce vibration-induced wear in interbedded sedimentary strata

These modifications extend service life by 40% in abrasive environments while preserving penetration efficiency. Thermal barrier coatings further reduce wear rates in high-temperature drilling (>300°C), particularly relevant in deep geothermal or mining applications.

Drilling Efficiency Gains with Rock Auger Bullet Teeth in Hard Rock

Penetration Rate Improvement: Data from Comparative Field Trials

Testing in different rock types like granite, basalt, and quartzite shows that these special rock auger bullet teeth can boost how fast they drill through really hard rock (over 60 MPa compressive strength) by somewhere between 40% and maybe even 60%. The shape of these teeth matters a lot too. They're cone shaped so they put all the force into a tiny spot on the rock surface. This actually helps break the rock apart rather than just pushing against it or making it shiny, which is what happens with those flat or chisel looking teeth most of the time. No more getting stuck with bit balling problems either, so the drilling keeps going at a steady pace. Real world results from field operators show that boring a 30 meter hole takes around 2.5 hours less in granite when using these teeth. That adds up to roughly 22% more work done each day compared to traditional methods.

Energy Efficiency and Downtime Reduction in Abrasive Strata

When it comes to drilling through quartz rich layers, the improved design actually brings down the torque needed somewhere around 18 to 25 percent. That means less fuel gets burned and the whole rig experiences significantly less wear and tear over time. The tungsten carbide material used in these bits holds up way better too. Standard alloy teeth just don't cut it when facing really rough terrain. We've seen field tests where these special bits last three times longer before needing replacement. Instead of changing out bits every 80 meters like normal practice, operators can now go all the way to 240 meters before maintenance is required. And let's not forget the bottom line impact. Field data shows that this translates into about 35% fewer unexpected stoppages during operations. For actual hard rock drilling projects across North America, companies report saving roughly $17 for each meter drilled thanks to these improvements. Not bad for something that initially seems so technical.

Extended Tool Life: Wear Resistance and Longevity of Rock Auger Bullet Teeth

Carbide Bullet Teeth Durability vs. Conventional Teeth in Moderately and Extremely Hard Rock

Tungsten carbide bullet teeth maintain cutting integrity for over 1,000 operational hours in abrasive strata–tripling the lifespan of conventional alloy teeth in formations exceeding 60 MPa compressive strength. This durability stems from three interrelated advantages:

- Superior wear resistance: Carbide tips exhibit 68% less material loss in granite drilling tests (Drilling Efficiency Journal, 2023)

- Impact resilience: Lower fracture incidence in boulder-rich or variable-density formations

- Modular replacement efficiency: Quick-swap shank designs cut maintenance downtime by 40%

The extended service life directly translates to cost savings, with operations reporting up to 70% reduction in tooth replacement expenses when drilling through hard quartzite and basalt layers.

Application Integration: Matching Rock Auger Bullet Teeth to Equipment and Job Requirements

Design Compatibility with Auger Diameter, Flight Pitch, and Torque Profile

Getting Rock Auger Bullet Teeth properly integrated means paying attention to three main factors about the equipment they're going on: the size of the auger itself, how far apart those spiral parts are spaced, and what kind of torque the machine can handle. When it comes to the shape of these teeth, their design needs to fit with the diameter of the auger so forces get spread out evenly across the whole cutting surface. The flight pitch, which is basically just measuring how far apart those spiral sections are from each other, plays a big role in how fast material gets removed and whether things might start to clog up. For steeper pitches where the spirals are closer together, we need specific tooth arrangements that help push away cuttings better when working through tough or sticky ground conditions. The torque coming from the drilling rig has to line up with what the teeth can actually withstand without breaking down. If this balance isn't right, especially in rock formations harder than 60 MPa, wear happens much faster according to a study published last year in Drilling Tech Review. Before installation always double check those shank measurements and how everything mounts onto the equipment specs sheet. Skipping this step could lead to some pretty expensive breakdowns down the road.

FAQ

What are rock auger bullet teeth?

Rock auger bullet teeth are drilling components designed with a cone shape to penetrate hard rock formations effectively. They focus drilling power into small spots, improving efficiency.

How do tungsten carbide bullet teeth improve drilling?

Tungsten carbide bullet teeth improve drilling by reducing energy requirements, increasing penetration rate, and minimizing downtime due to their geometry and material properties.

What are the benefits of using carbide bullet teeth in hard rock drilling?

Benefits include superior durability, wear resistance, and cost savings due to extended tool life and reduced tooth replacement expenses.

Table of Contents

- Rock Auger Bullet Teeth Design: Geometry and Material Science for Hard Rock Penetration

- Drilling Efficiency Gains with Rock Auger Bullet Teeth in Hard Rock

- Extended Tool Life: Wear Resistance and Longevity of Rock Auger Bullet Teeth

- Application Integration: Matching Rock Auger Bullet Teeth to Equipment and Job Requirements