How Core Barrel and Auger Drilling Work: Key Mechanisms Compared

Core Barrel Drilling: Principle and Sample Integrity Advantages

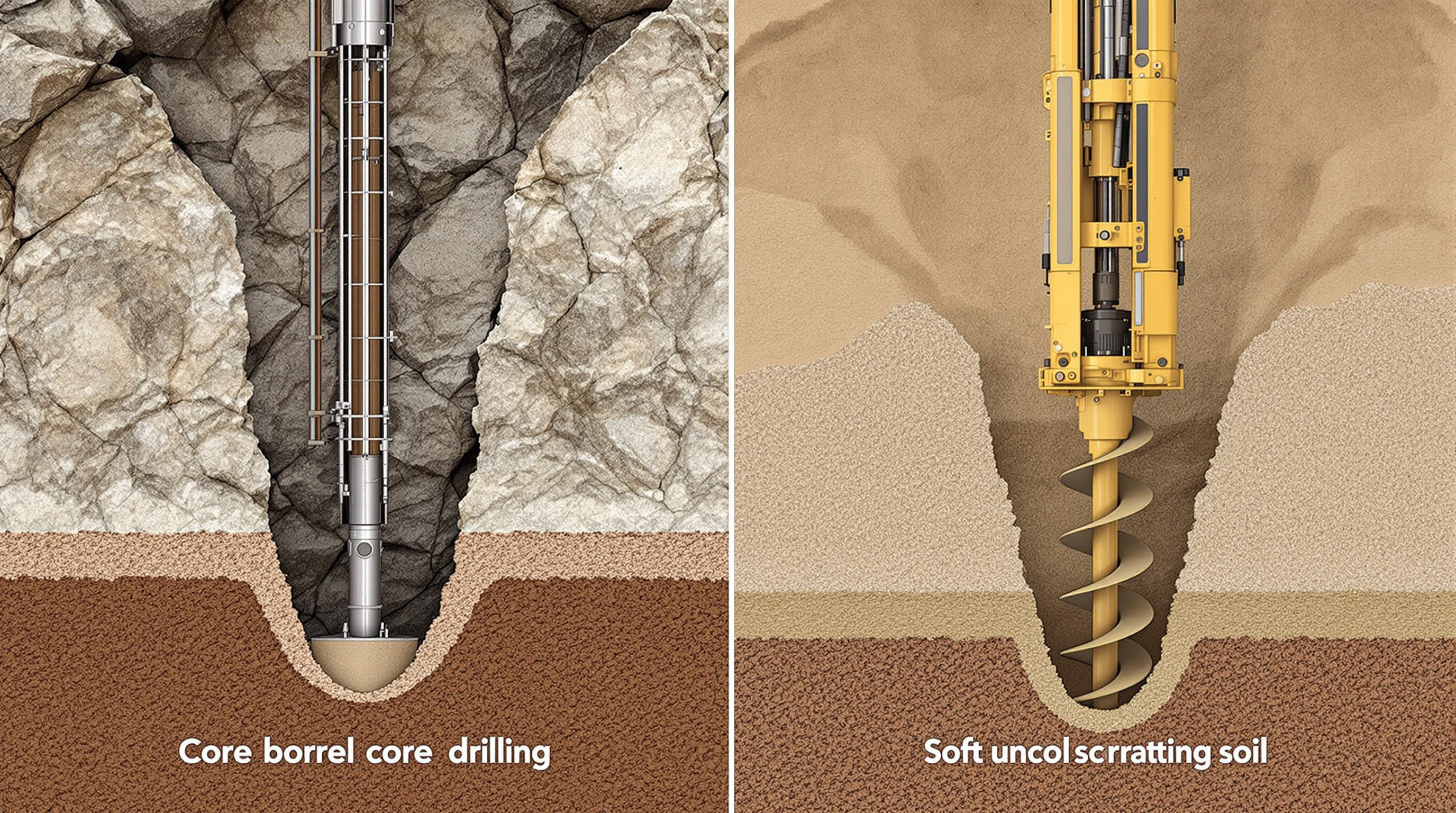

The core barrel drilling technique involves a hollow rotating barrel equipped with cutting teeth that pulls out solid cylindrical samples from underground formations. According to research published by the Geotechnical Institute last year, this approach maintains stratigraphic layering at around 94% accuracy rate, which is why engineers rely on it so heavily when they need detailed geological information for construction or mining projects. Modern equipment comes with sophisticated stabilization mechanisms that actually reduce sample disturbance significantly, even when working through broken or fractured rock formations. Recent field tests conducted in 2023 showed something pretty remarkable too core barrels cut down material loss by approximately 81% over traditional methods when dealing with tough limestone deposits. That kind of performance makes them clearly better suited for preserving sample quality across different types of geological surveys.

Auger Drilling: Mechanism and Efficiency in Unconsolidated Ground

The auger drilling method uses a spiral shaped blade that pulls loose dirt and sediment up from underground. When working through clay and sandy ground, these augers can drill about three times quicker than traditional core barrels according to recent data from the 2024 Drilling Efficiency Report. The special flight design on most augers helps keep them clean during operation, which cuts down on the time wasted clearing out holes. This really matters at sites where crews need to complete over fifty shallow boreholes each day. On the downside though, this mixing action tends to blend different soil layers together. For projects needing precise environmental assessments or detailed geological profiles, this blending effect makes auger drilling less suitable compared to other methods.

Fundamental Differences in Output: Core Recovery vs. Cuttings Removal

The primary distinction lies in material retrieval:

- Core barrels produce undisturbed, structurally intact samples ideal for lab testing

- Augers generate mixed cuttings suitable for rapid site characterization

A 2023 comparison of 12 drilling projects showed core methods took 40% longer but delivered 92% higher data accuracy in mineral exploration. This trade-off explains why 78% of geotechnical engineers prioritize core drilling for critical infrastructure despite higher upfront costs.

Performance in Different Ground Conditions: Core Barrel vs. Auger

Core Barrel Effectiveness in Hard Rock and Fractured Formations

Core barrels really shine when dealing with tough materials like hard rock formations and broken ground. These tools work their magic by focusing all that cutting power into one track design. According to Terex reports from 2022, these barrels can recover around 98% of samples in granite and basalt conditions. That kind of performance makes them pretty much essential for anyone doing serious mineral hunting or checking out geology in areas prone to earthquakes. The fact that they pull out complete core samples means engineers get solid information to work with when planning projects or mapping resources underground.

Auger Advantages in Cohesive Soils and Unconsolidated Ground

Auger systems work really well in cohesive soils such as clay and those loose sediment types because their continuous flight design just keeps cutting through and pulling out material as it goes. Some recent field tests from last year found that augers can drill those 25 meter holes about 40 percent quicker compared to traditional core barrels when dealing with silty conditions. The hollow stem versions are especially handy since they let workers take soil samples right there on site without having to pull the whole tool out first. This saves time during environmental checks or when testing foundations in softer urban areas where getting equipment in and out can be a hassle.

Challenges Each Tool Faces: When Performance Declines

Core barrels have real trouble working through unconsolidated sediments. Sandy or gravelly soils tend to push core loss rates up anywhere from 35 to 50 percent according to field reports. Augers tell a different story though. These tools wear out fast when faced with rocky terrain, especially in areas with conglomerate layers where torque requirements just go through the roof, as noted in Drilling Journal last year. When operators try using these tools beyond what they're designed for, projects run into all sorts of problems. Delays happen, costs balloon, and nobody wants that. Equipment mismatches are actually responsible for about two thirds of those unexpected budget jumps during exploration work.

Case Study: Selecting the Right Tool for Mixed Ground Conditions

During work on a coastal construction site, workers found themselves dealing with tricky ground conditions featuring alternating layers of sandstone between 8 and 12 meters deep, followed by saturated silt from around 16 to 20 meters below surface level. The team initially relied on core barrels to collect rock samples above the 15 meter mark, but when they needed to get into those deeper sediments, they switched over to dual tube augers instead. This combination method cut down waiting time at each borehole location by about 22 hours without sacrificing much quality either. Samples came back accurate about 95% of the time too. What this shows is that picking the right tools for different soil types really pays off when working through complicated underground formations.

Drilling Speed, Cost, and Operational Efficiency Compared

Time and Labor Costs: Core Barrel vs. Auger Setup and Execution

Core barrel drilling requires specialized rigs and skilled operators, adding 30â45 minutes to setup time compared to auger systems. However, its precision reduces long-term labor costs in projects requiring high-fidelity data. Auger drilling simplifies execution in soft soils, with projects reporting 20% faster completion times in unconsolidated ground (Geotechnical Survey Quarterly 2023).

Mobilization and Equipment Costs in Urban and Remote Sites

Mobilizing core barrel equipment costs 25â40% more in urban areas due to larger rig sizes and noise mitigation needs. In remote regions, auger systems benefit from modular designsâfield data from 2022 showed 18% lower transport costs compared to core barrel rigs.

Operational Speed: Short-Range vs. Long-Range Boreholes

| Borehole Type | Core Barrel Speed (m/hr) | Auger Speed (m/hr) |

|---|---|---|

| Short-Range (<30m) | 2.1â3.4 | 4.8â6.2 |

| Long-Range (>100m) | 1.8â2.5 | Not Recommended |

Core barrels maintain stable performance at depth, while auger efficiency declines sharply beyond 50m in most ground types.

Cost-Efficiency Trade-Offs: Sample Quality vs. Project Budget

Industry studies show core barrel systems incur 35â50% higher hourly costs, justified when project success depends on intact stratigraphic samples. For contamination screening or preliminary surveys, auger drilling provides sufficient data at 60â70% lower cost per meter.

How to Choose the Right Tool: A Decision Framework for B2B Projects

Decision Matrix Based on Soil Type and Project Depth

Selecting between core barrel and auger drilling hinges on ground composition and project depth. A simplified decision matrix guides initial tool selection:

| Soil/Rock Type | Depth Range | Recommended Tool | Key Advantage |

|---|---|---|---|

| Hard rock/fractured bedrock | 10â200m+ | Core Barrel | Preserves stratigraphic integrity |

| Unconsolidated sand/clay | 3â30m | Auger | Rapid cuttings removal |

| Mixed conditions | 15â50m | Hybrid systems* | Balances speed and accuracy |

*Combines auger flights for shallow layers and retrievable core barrels for deep sampling

Core barrels are preferred for mineral exploration or geotechnical assessments in metamorphic rock, where sample fidelity is critical. Auger systems dominate in environmental drilling for contaminant mapping in silt/clay, where 83% of contractors prioritize speed over core quality (Geodrill 2023).

When to Use Core Barrel for High-Fidelity Geological Data

Choose core barrel drilling when projects require:

- Undisturbed sampling: Essential for ore grade analysis or fault zone characterization

- Deep drilling: Triple-tube systems maintain >95% recovery at 150m depths

- Regulatory compliance: Required by ASTM D2113 for subsurface engineering studies

A 2022 analysis of 12 mining projects found core barrel use reduced re-drilling costs by $28k/site by eliminating ambiguous stratigraphic interpretations.

When Auger Is the Practical Choice for Speed and Simplicity

Auger drilling excels in:

- Shallow geotechnical investigations (<25m): Completes 85% of boreholes in under 4 hours

- Urban utility surveys: Minimizes road closure durations with 20â40m/day progress rates

- Budget-constrained projects: Auger contracts average 35% lower mobilization costs versus core rigs

A 2023 comparative study found augers achieved 92% cost-efficiency in homogeneous clay sitesâbut only 41% in layered glacial till, reinforcing the need for condition-based tool selection.

Innovations Enhancing Core Barrel and Auger Drilling Performance

Advancements in Core Barrel Design for Improved Recovery

Today's core barrel systems combine strong alloys with real time data collection to keep samples intact during drilling operations. PDC bits stand up better against tough rock formations, and the modular setup means crews can swap out components fast when geological conditions change on site. Downhole sensors continuously monitor temperature shifts and pressure changes underground, helping operators fine tune their approach without sacrificing the quality of recovered cores. Field tests indicate these improvements cut core losses by around 35 percent, which makes a big difference in areas where rock is cracked or rich in minerals. Copper miners have seen firsthand how these adaptable systems tackle contamination problems in loose soil layers, giving geologists much clearer data for building resource models that actually reflect what's happening below ground.

Efficiency Upgrades in Modern Auger Systems

The world of auger drilling has come a long way thanks to automated feed systems and rigs connected to the internet of things that cut down on hands-on labor requirements. Modern track mounted units now feature artificial intelligence for positioning control, keeping torque and rotation at just the right levels. Field tests show these machines can drill through cohesive soils about forty percent quicker than traditional methods. Exploration crews working in gold fields have noticed significant improvements in identifying anomalies because their equipment automatically adjusts itself according to what the soil density sensors detect. This means less time getting gear into place when working far from civilization. Another practical improvement comes from sealed flight designs with special coatings that prevent sticking issues when dealing with wet clay conditions. All these technological enhancements are making augers increasingly popular among contractors who need reliable results while keeping costs under control for both environmental sampling projects and fast turnaround geotechnical assessments.

FAQ

What is the main difference between core barrel and auger drilling?

Core barrel drilling retrieves undisturbed cylindrical samples, ideal for accurate geological data, while auger drilling uses spiral blades to pull up mixed cuttings suitable for fast site characterization.

Which drilling method is better for hard rock formations?

Core barrel drilling is more effective for hard rock and fractured formations due to its ability to recover around 98% of samples intact, making it essential for mineral exploration and geotechnical assessments.

When should auger drilling be used?

Auger drilling should be used in cohesive soils and unconsolidated grounds where rapid hole completion is essential, especially for shallow geotechnical investigations and urban utility surveys with budget constraints.

What are the cost benefits of using auger drilling?

Despite lower sample accuracy, auger drilling provides significant cost savings, achieving 60-70% lower costs per meter compared to core barrel systems, making it suitable for preliminary surveys and budget-constrained projects.

Table of Contents

- How Core Barrel and Auger Drilling Work: Key Mechanisms Compared

- Performance in Different Ground Conditions: Core Barrel vs. Auger

- Drilling Speed, Cost, and Operational Efficiency Compared

- How to Choose the Right Tool: A Decision Framework for B2B Projects

- Innovations Enhancing Core Barrel and Auger Drilling Performance

- FAQ