Mga Pangunahing Konsepto ng Casing pipe Kalkulasyon ng Kapal ng Wall sa Ilalim ng Panlabas na Presyon

Paano Nakakaapekto ang Panlabas na Presyon ng Lupa at Hydrostatic sa Kahusayan ng Casing

Ang pag-compress ng lupa mula sa labas at ang bigat ng tubig sa itaas ay nagbubuo ng mga puwersa na nagsisikap na humigit sa mga gilid ng casing, na naglalagay nito sa panganib. Habang lumalalim ang pag-bore, halimbawa mga 100 metro pababa, ang presyon mula sa tubig alon ay umaabot ng humigit-kumulang 1.02 MPa ayon sa datos mula sa industriya noong 2023. Lumalala pa ang sitwasyon kapag kinakaharap ang mga mahirap na formasyon tulad ng mga nag-swelling na layer ng luwad na talagang nagpapataas pa ng mga pwersang pahalang na ito. Lahat ng mga stress na ito kapag pinagsama-sama ay nagdudulot ng kung ano ang tinatawag ng mga inhinyero na circumferential stress sa paligid ng mga pader ng tubo. Ibig sabihin, mahalagang tumpak na makalkula ang eksaktong kapal ng mga pader na ito upang maiwasan ang mga kritikal na pagkabigo kung saan ang casing ay maaaring mawasak sa ilalim ng presyon o lumuwang palabas sa parehong tuwid at nakamiring mga butas.

Mga Pangunahing Prinsipyo ng Pagkalkula ng Kapal ng Pader ng Tubo sa Ilalim ng Panlabas na Presyon

Kapag nagtatrabaho sa kapal ng casing wall sa ilalim ng panlabas na presyon, karamihan sa mga inhinyero ay sumangguni sa mga pamantayan ng ASME B31.3 para matukoy ang kakayahang lumaban sa pagbagsak. Meron itong pangunahing formula na ginagamit: t_min ay katumbas ng (panlabas na presyon minultiply sa panlabas na diametro) hinati ng (dalawang beses ang lakas ng materyales na nagtatag at kahusayan ng joint plus 0.4 beses ang panlabas na presyon). Para maibahagi ito nang simple, ang t_min ay nangangahulugang pinakamaliit na kinakailangang kapal, ang P_ext ay ang sinusukat nating panlabas na presyon, ang D_o ay ang panlabas na diametro ng tubo, ang S ay kumakatawan sa lakas ng materyales, at ang E ay ang kahusayan ng joint. Ang mga aplikasyon sa tunay na mundo ay nangangailangan ng paghahanap ng tamang balanse sa pagitan ng mga margin ng kaligtasan at mga aktwal na limitasyon sa produksyon. Kung sobrang kapal ng mga pader, ito ay magdaragdag ng malaking gastos, humigit-kumulang $18 hanggang $42 bawat linear foot ayon sa mga kamakailang datos mula sa SPE Drilling noong 2022.

Ang Papel ng Formasyon at Geopressure Data sa Paunang Pagtataya ng Kapal

Ang geomekanikal na pagmomodelo ng uri ng formasyon at gradient ng pressure ng poro ay nagtatakda ng baseline na kapal na kailangan. Ang formasyong shale na may 2.1+ sg equivalent na timbang ng luwad ay nangangailangan ng 15–25% mas makapal na pader kumpara sa matatag na sandstone na strata. Ang real-time na logging-while-drilling (LWD) na datos ay nagbibigay-daan na ngayon sa dinamikong mga pag-aayos habang isinasagawa ang run-in-hole operations.

Kaso: Mahabang Borehole sa Sichuan Basin na Kinakaharap ang Mataas na Panlabas na Mga Karga

Isang 7,850m gas well sa Longmaxi shale sa Sichuan ay nangailangan ng N80 casing na may 18.24mm kapal ng pader upang umangkop sa 138MPa na panlabas na mga karga. Ang post-installation na caliper logs ay nagkumpirma ng <0.3% na ovality kahit ang tectonic stresses mula sa tatlong fault zone, na nagpapatunay sa ASME-based na diskarte sa disenyo.

Lumalagong Tendensya: Real-Time na Geopressure Modeling sa Disenyo ng Casing

Ang mga advanced na operator ay nag-i-integrate na ngayon ng machine learning kasama ang distributed fiber-optic sensing upang i-update ang mga casing model habang nagpapakulo ng semento. Ayon sa mga teknikal na papel ng SPE, ang approach na ito na closed-loop ay binawasan ang mga insidente ng pagbagsak ng 41% sa HPHT na mga balon sa 2022 na mga field trial.

Pag-iwas sa Buckling at Pagbagsak Dahil sa Pag-compress sa Mga Instalasyon ng Malalim na Casing

Mga Insidente sa Field ng Casing Collapse Dahil sa Compression at Buckling

Isang pag-aaral noong 2022 ng 17 proyekto sa malalim na tubig ay nagpahiwatig na ang 35% ng mga deformed casing ay nagmula sa hindi nadiagnose na buckling, kung saan ang average na gastos ng pagkumpuni ay $2.1M bawat insidente. Ang mga pagbagsak na ito ay karaniwang nangyayari ilang linggo o buwan matapos ang pag-install, na nagpapakita ng pagkaantala ng mga reaksyon ng istraktura sa patuloy na panlabas na mga karga.

Mga Mekaniks sa Likod ng Buckling at Compression Failure ng Mga Tubo sa Casing

Kapag ang axial compressive stresses ay lumampas sa kayang ihalad ng casing sa critical load point nito, magsisimula ang buckling. Ang formula para iyang kalkulahin ang critical load ay ganito: Pcr equals pi squared na minultiply ng E times I na hinati ng (K times L) squared. Payagan mo akong i-explain ang mga variable nang mabilis—ang E ay kumakatawan sa elastic modulus, ang I ay moment of inertia, ang K ay end condition factor, at ang L ay ang unsupported length ng casing. Ngayon, kapansin-pansin, ang mga shale formation na may swelling clays ay nakalilikha ng mas malaking lateral forces kaysa karaniwang nakikita. Mayroon itong napakahalagang epekto sa critical load value. Sa katunayan, ipinapakita ng mga pag-aaral na bumababa ang Pcr ng halos 40% sa mga shale na kondisyon kumpara sa nakikita natin sa mga sandstone layer. Napakalaking pagkakaiba at isang bagay na dapat tandaan ng mga inhinyero sa panahon ng pagdidisenyo.

Epekto ng Unsupported Length sa Risk ng Buckling sa Horizontal at Deep Wells

Ang mga horizontal na wellbores ay nagpapakita ng 2.3Ö na mas mataas na posibilidad ng buckling kaysa sa mga vertical dahil sa mas mahabang span ng hindi sinusuportahang casing. Sa Permian Basin, binawasan ng mga operator ang mga insidente ng pagbagsak ng 62% matapos limitahan ang mga hindi sinusuportahang segment sa ™ 12 metro sa pamamagitan ng mas mahusay na paglalagay ng centralizer.

Kaso: Offshore na Well sa Gulf of Mexico na may Post-Installation Buckling

Isang proyektong deepwater noong 2021 sa 3,500m TVD ay nakaranas ng ovalization ng casing (17% na pagbawas ng diameter) sa loob ng 90 araw ng pagkumpleto. Ang finite element analysis ay nag-ugat ng pagkabigo sa isang 14-metro na hindi sinusuportahang seksyon na napailalim sa 12,500 psi na panlabas na presyon mula sa mga paggalaw ng overburden.

Estratehiya: Pag-optimize ng Suporta gamit ang Centralizers at Cement Bonding upang Bawasan ang Effective Length

Ang mga pagsubok sa North Sea ay nagpakita na ang mga centralizer na may agwat na 8-metro na kasama ang mga system ng resin-based na semento ay nagpabuti ng pagbabahagi ng karga ng 78%. Ang diskarteng ito ay nagbaba sa effective unsupported length sa ilalim ng 5 metro, kahit sa mga lubhang nabaluktot na landas ng well.

Pag-optimize ng Do/T Ratio para sa Structural Stability sa Mahirap na Formations

Mga Pagkabigo sa Pagkasumpa na Naka-link sa Mataas na Diameter-to-Thickness (Do/T) Ratio

Nagpapakita ang field data na 47% ng mga pagkabigo ng casing pipe sa hindi matatag na shale formations ay nangyayari sa mga pipe na may Do/T ratio na higit sa 30:1 (Drilling Integrity Report 2023). Ang mas mataas na ratio ay nagbawas ng kakayahang umangkop ng 18–22% bawat 5-unit na pagtaas ng ratio, dahil ang mas manipis na pader ay nag-uunat sa ilalim ng asymmetric formation pressures.

Epekto ng Do/T Ratio sa Structural Stability ng Casing sa Ilalim ng Load

Ang ugnayan sa pagitan ng Do/T ratio at critical collapse pressure ay sumusunod sa isang hindi linear na pattern:

| Do/T Ratio | Collapse Pressure (psi) | Deformation sa Pagkabigo (%) |

|---|---|---|

| 25:1 | 5,200 | 2.1 |

| 30:1 | 3,800 | 4.7 |

| 35:1 | 2,100 | 8.9 |

Data mula sa API 5C3 collapse tests sa P110 casing material

Case Study: Standard kumpara sa Slimhole Casing Performance sa Hindi Matatag na Strata

Isang proyekto noong 2022 sa Sichuan Basin ay nagtulad ng 9â…¥" casing (Do/T 28:1) sa slimhole na 7" designs (Do/T 22:1). Pagkalipas ng 18 buwan, ang standard casing ay nagpakita ng 3.2mm ovalization kumpara sa 0.8mm naman sa slimhole na konpigurasyon sa ilalim ng magkaparehong geopressures.

Paglipat ng Industriya sa Mas Mababang Do/T Ratio sa Mataas na Panganib at Malalim na Aplikasyon

Ang mga operator sa Gulf of Mexico ay nagsisiguro na ang Do/T ratios ay <25:1 para sa mga balon na lampas sa 15,000ft TVD – isang 35% na pagbaba kumpara sa mga disenyo noong dekada 2010. Ito ay tugma sa bagong na-update na ASME B31.8 na mga gabay na nagpapahalaga sa mga panganib na geo-mechanical.

Estratehiya: Pagpili ng Optimal na Do/T Ayon sa Lalim, Presyon, at Uri ng Formasyon

Isang tatlong-tier na matrix sa pagpili ang nabuo:

- Do/T 15–20:1: Salt domes & tectonic zones (>10,000psi external)

- Do/T 20–25:1: Conventional reservoirs (5,000–10,000psi)

- Do/T 25–28:1: Mga matatag na formasyon (<5,000psi) na mayroong na-monitor na pressure regimes

Pagsusuri sa Disenyo ng Casing Para sa Mababang Internal na Presyon at Mga Kondisyon ng Vacuum

Pagsabog ng Casing Habang Nakasara at Nasa Iba pang Operasyon ang Balon

Kapag ang presyon sa loob ng casing pipes ay bumaba sa ilalim ng sukat ng puwersa mula sa labas habang ang well ay naka-shutdown o nasa maintenance, may tunay na panganib ng pagbagsak. Ayon sa isang pananaliksik na nailathala sa SPE Journal noong 2022, halos isang-kapat ng lahat ng casing failures sa mababang presyon ng mga well ay naganap habang isinasagawa ang maintenance, partikular na nang bumaba ang internal pressure sa ilalim ng 5 MPa. Ang karamihan ay hindi napapansin ay ang mga sitwasyon ng pressure inversion kung saan ang mga puwersa mula sa labas ay talagang nananaig sa mga puwersa sa loob. Karamihan sa tradisyunal na casing designs ay hindi sineseryoso ang aspetong ito, bagaman maaari itong magdulot ng malubhang problema kung hindi papansinin.

Kahalagahan ng Pag-verify ng Kapal ng Pader para sa Vacuum at Mga Transient Pressure na Sitwasyon

Ang pag-verify ng kapal ng casing wall ay nangangailangan ng simulation ng mga kondisyon ng full-vacuum (0 psi internal pressure) kasama ang pinakamataas na inaasahang panlabas na karga. Mahahalagang pagsasaalang-alang ay kinabibilangan ng:

- Mga pagbabago ng presyon habang nag-i-iniksyon/pagkuha ng CO₂

- Pagsisimba ng semento sa loob ng 20+ taong buhay ng kwell

- Epekto ng pag-urong dahil sa init sa mga kapaligirang artiko o ilalim ng dagat

API TR 5C3 mga gabay ay inirerekomenda ang paglalapat ng pinakamaliit na salaping seguridad na 1.25 para sa mga sitwasyon na walang hangin – 20% na pagtaas kumpara sa karaniwang mga salik sa disenyo ng presyon.

Kaso: Onshore na Carbon Capture Storage na May Vacuum Cycling

Isang proyekto sa carbon sequestration sa Permian Basin ay nakaranas ng 12 mm na pag-ikot sa production casing pagkatapos ng 18 buwan ng vacuum-pressure cycling. Ang pagsusuri pagkatapos ng pagkabigo ay nagbunyag ng:

| Parameter | Halaga ng Disenyo | Tatag na load |

|---|---|---|

| Min Internal Pressure | 2 MPa | -0.3 MPa |

| Cyclic Stress Range | 180 MPa | 210 MPa |

| Ang insidente ay nag-udyok sa mga operator na mag-adopt ng dynamic pressure monitoring systems at dagdagan ang wall thickness ng 15% para sa susunod na CCS wells. |

Paglalapat ng Safety Factors para sa Maaasahang Pagganap sa Ilalim ng Mababang Internal Pressure

Modern casing design workflows incorporate probabilistic load modeling upang tugunan ang mga hindi tiyak na presyon sa Enhanced Oil Recovery (EOR) at aplikasyon sa geothermal. Kabilang dito ang pinakamahusay na kasanayan:

- Paggamit ng triaxial stress analysis sa halip na tradisyunal na biaxial models

- Pagpapatupad ng real-time pressure boundary condition updates sa pamamagitan ng SCADA integration

- Tinutukoy ang mga uri ng bakal na lumalaban sa pagbagsak tulad ng T95 para sa matinding kondisyon ng serbisyo

Tinutukoy ang mga uri ng bakal na lumalaban sa pagbagsak tulad ng T95 para sa matinding kondisyon ng serbisyo.

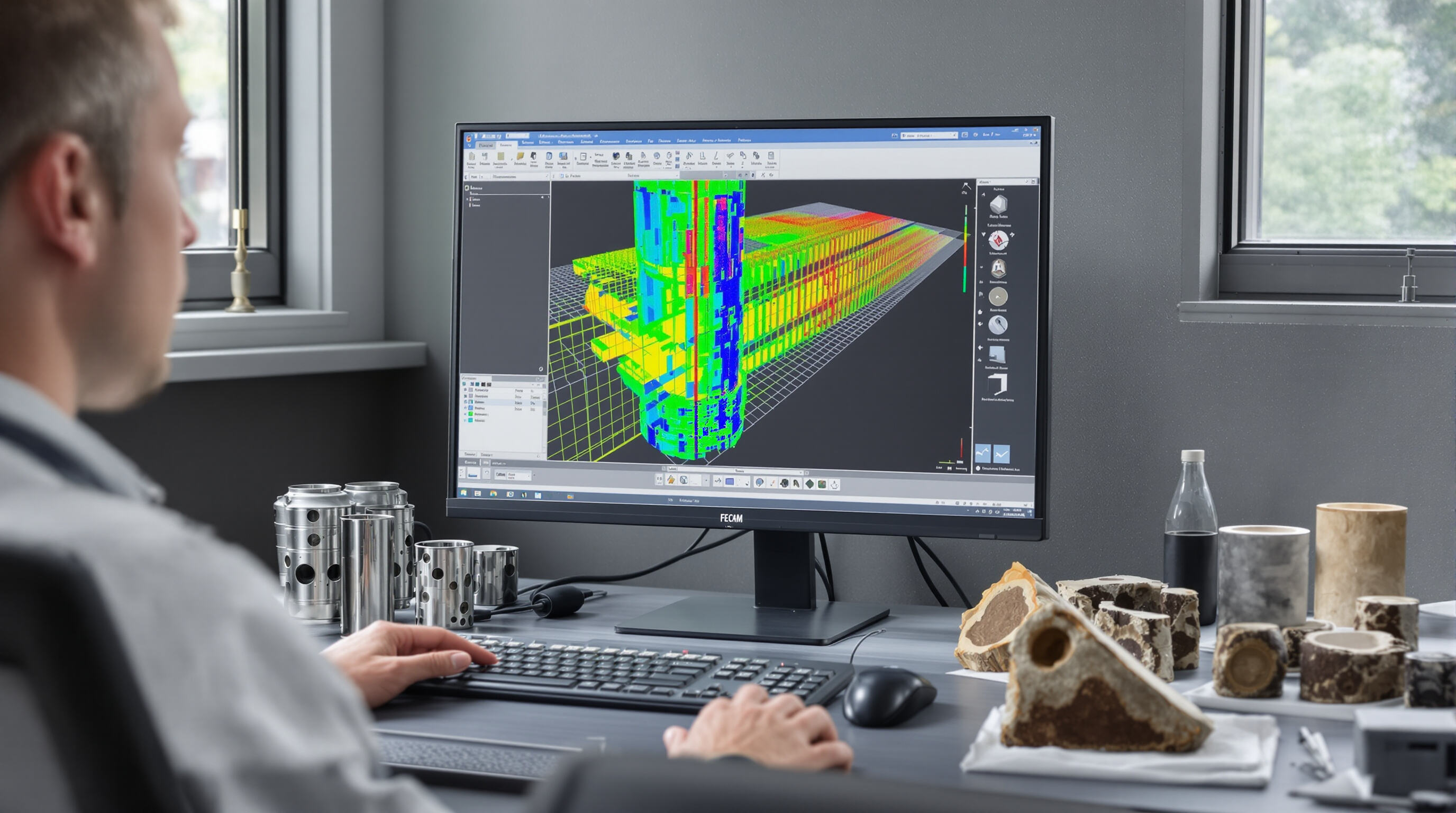

Advanced Mechanical Modeling at Finite Element Analysis sa Casing System Design

Hindi Pantay na Distrubusyon ng Tensyon sa Paligid ng Casing Dahil sa Interaksyon ng Semento-Formasyon

Ang mga modernong sistema ng casing ay nakikitungo sa mga kumplikadong sitwasyon ng presyon habang ang semento ay nakikipag-ugnayan sa paligid na formasyon upang makabuo ng tiyak na mga rehiyon ng presyon. Hindi lang mga karaniwang panlabas na presyon ang tinutukoy dito. Kapag nakasalikod ang semento sa mga materyales ng formasyon, talagang nalilikha nito ang hindi pantay na distribusyon ng presyon sa kabuuan ng casing. Ang ganitong uri ng imbalance ay nagpapabilis sa pagkasira o pagkasuot nang mas mabilis kaysa inaasahan ng karamihan. Ang mga inhinyero ay nagsimulang gumamit ng isang proseso na tinatawag na Finite Element Analysis, o FEA para maikli, upang mas maunawaan ang lahat ng ito. Gamit ang mga tool sa FEA, maaari nilang tingnan kung paano kumikilos ang semento sa pakikipag-ugnayan sa casing, hanggang sa pinakamunting detalye na sinusukat sa micron. Kung ano ang kanilang natutuklasan ay kadalasang nakakapagtaka dahil maraming mga mahihinang punto ang hindi kailanman lumalabas kapag ginagamit ang mga lumang paraan ng pagkalkula na umaasa sa linear na paggana.

Mga Pag-unlad sa Mekanikal na Pagguguhit ng Casing sa ilalim ng In-Situ Stresses

Ang mga kamakailang pag-unlad sa multi-physics simulations ay kasalukuyang nagsasama ng temperatura gradients, rock plasticity, at fluid-induced corrosion nang sabay-sabay. Isang pag-aaral noong 2024 ay nagpatunay sa kawastuhan ng mga modelong ito gamit ang field data mula sa 17 geothermal wells, na nakamit ang 92% na katumpakan sa pagtaya ng casing deformation thresholds. Ang ganitong katiyakan ay nagpapahintulot sa mga inhinyero na maayos nang dinamiko ang kapal ng pader batay sa real-time geopressure updates.

Finite Element Analysis ng Casing-Cement-Formation System: Pagpigil sa Debonding at Microannuli

Tunay na halaga ng FEA ay lumilitaw sa pagsusuri ng tripartite systems—casing, cement sheath, at nakapaligid na bato. Sa pamamagitan ng simulation ng thermal cycling at pressure shocks, natutukoy ng mga inhinyero ang mga panganib ng debonding sa mataas na entalpiyang reservoir. Isang pionerong pamamaraan noong 2023 ang nagbawas ng microannuli formation ng 40% sa sour gas wells sa pamamagitan ng pag-optimize ng cement elastic moduli gamit ang FEA-driven material selection.

Kaso: HPHT Well sa Tarim Basin na Napatunayan ng Buong-System FEA

Ang proyektong HPHT na isinasagawa sa Tarim Basin ng Tsina ay talagang nagpapakita ng husay ng FEA. Ang grupo ng inhinyero ay nagpatakbo ng mga simulation gamit ang isang sopistikadong software sa finite element analysis para mahulaan kung paano hahawakan ng mga casing ang matinding kondisyon - tinitingnan natin ang presyon ng formasyon na umaabot sa 162 MPa at temperatura na umaabot sa 204 degree Celsius. Matapos ang pagbubungkal, tiningnan nila ang aktuwal na mga sukat laban sa mga hinulaan ng simulation. Ano ang kanilang natagpuan? May kaunti lamang sa kalahating porsiyentong pagkakaiba sa pagitan ng tunay na datos at mga modelo sa kompyuter. Ang ganitong antas ng katiyakan ay nagbibigay tiwala sa mga inhinyero habang kinakaharap ang ganitong uri ng mapigil na kondisyon sa ilalim ng lupa kung saan ang mga pagkakamali ay maaaring magmhal.

Pagsasama ng FEA at Field Data upang Ikonekta ang Agwat sa Pagitan ng Teorya at Pagganap

Ang mga nangungunang operator sa industriya ay nagsisimula nang magpadala ng impormasyon tungkol sa drilling telemetry pabalik sa kanilang mga FEA model ngayon a days. Tinutukoy namin dito ang mga bagay tulad ng vibration patterns, torque measurements, at mga biglang spike sa presyon habang nasa operasyon. Nang maisakatuparan nila ang ganitong uri ng feedback loop system, isang proyekto sa shale gas ang nakakita ng pagbaba ng mga casing failures ng mga 31% sa kabuuang 50 mga well. Talagang kahanga-hanga ang resulta kung ihahambing sa mga lumang pamamaraan kung saan umaasa lamang ang mga inhinyero sa static design calculations. Ang nakikita natin dito ay isang bagong paraan ng pagtingin kung paano nagtatagal ang mga casing sa paglipas ng panahon. Sa pamamagitan ng pagsasama ng computer simulations at tunay na datos mula sa aktwal na kondisyon sa pag-drill, lubos nang nagbago ang direksyon ng larangan tungkol sa tibay ng casing.

FAQ

Ano ang pangunahing layunin ng pagkalkula ng casing pipe wall thickness sa ilalim ng panlabas na presyon?

Ang pangunahing layunin ay tiyakin ang integridad ng istraktura ng casing pipes upang maiwasan ang pagguho o pagbaluktot sa ilalim ng mga presyon mula sa labas tulad ng pag-compress ng lupa at hydrostatic forces.

Paano nakatutulong ang ASME B31.3 standard sa pagkalkula ng kapal ng pader (wall thickness)?

Nagbibigay ang ASME B31.3 standard ng formula para sa pagtukoy ng minimum na kinakailangang kapal ng pader sa pamamagitan ng pag-consider ng presyon mula sa labas, ang panlabas na diametro ng tubo, lakas ng materyal (yield strength), at kahusayan ng joint.

Bakit naging mas mahalaga ang real-time geopressure modeling para sa disenyo ng casing?

Nagtutulong ang real-time geopressure modeling para sa mga dinamikong update at pag-aayos habang nangyayari ang operasyon, na malaking binabawasan ang panganib ng pagguho sa mga kumplikadong at mataas na presyon na kapaligiran.

Ano-ano ang ilang mahahalagang diskarte para maiwasan ang buckling at compression failures sa malalim na pag-install ng casing?

Ang mga estratehiya ay kinabibilangan ng pag-optimize ng suporta sa pamamagitan ng mga centralizer at cement bonding, pagbawas ng epektibong haba na hindi sinusuportahan, at paggamit ng finite element analysis para sa tumpak na modeling ng distribusyon ng stress.

Bakit mahalaga ang Do/T ratio sa pagkontrol ng mga pagbagsak ng casing pipe?

Ang Do/T ratio ay direktang nakakaapekto sa kakayahang umlaban sa pagbagsak; ang mas mataas na ratio ay kaugnay ng mas mataas na rate ng pagbagsak, kaya mahalaga ang optimization upang mapanatili ang istruktural na katatagan.

Paano ang finite element analysis (FEA) ay nagbabago sa disenyo ng sistema ng casing?

Ang FEA ay nagbibigay-daan sa simulation ng mga kumplikadong interaksyon ng casing-cement-formation, nagbibigay ng detalyadong kaalaman tungkol sa distribusyon ng stress at nagpapahintulot sa optimization para sa pinahusay na tibay at paglaban sa mga pagbagsak.

Talaan ng mga Nilalaman

-

Mga Pangunahing Konsepto ng Casing pipe Kalkulasyon ng Kapal ng Wall sa Ilalim ng Panlabas na Presyon

- Paano Nakakaapekto ang Panlabas na Presyon ng Lupa at Hydrostatic sa Kahusayan ng Casing

- Mga Pangunahing Prinsipyo ng Pagkalkula ng Kapal ng Pader ng Tubo sa Ilalim ng Panlabas na Presyon

- Ang Papel ng Formasyon at Geopressure Data sa Paunang Pagtataya ng Kapal

- Kaso: Mahabang Borehole sa Sichuan Basin na Kinakaharap ang Mataas na Panlabas na Mga Karga

- Lumalagong Tendensya: Real-Time na Geopressure Modeling sa Disenyo ng Casing

-

Pag-iwas sa Buckling at Pagbagsak Dahil sa Pag-compress sa Mga Instalasyon ng Malalim na Casing

- Mga Insidente sa Field ng Casing Collapse Dahil sa Compression at Buckling

- Mga Mekaniks sa Likod ng Buckling at Compression Failure ng Mga Tubo sa Casing

- Epekto ng Unsupported Length sa Risk ng Buckling sa Horizontal at Deep Wells

- Kaso: Offshore na Well sa Gulf of Mexico na may Post-Installation Buckling

- Estratehiya: Pag-optimize ng Suporta gamit ang Centralizers at Cement Bonding upang Bawasan ang Effective Length

-

Pag-optimize ng Do/T Ratio para sa Structural Stability sa Mahirap na Formations

- Mga Pagkabigo sa Pagkasumpa na Naka-link sa Mataas na Diameter-to-Thickness (Do/T) Ratio

- Epekto ng Do/T Ratio sa Structural Stability ng Casing sa Ilalim ng Load

- Case Study: Standard kumpara sa Slimhole Casing Performance sa Hindi Matatag na Strata

- Paglipat ng Industriya sa Mas Mababang Do/T Ratio sa Mataas na Panganib at Malalim na Aplikasyon

- Estratehiya: Pagpili ng Optimal na Do/T Ayon sa Lalim, Presyon, at Uri ng Formasyon

-

Pagsusuri sa Disenyo ng Casing Para sa Mababang Internal na Presyon at Mga Kondisyon ng Vacuum

- Pagsabog ng Casing Habang Nakasara at Nasa Iba pang Operasyon ang Balon

- Kahalagahan ng Pag-verify ng Kapal ng Pader para sa Vacuum at Mga Transient Pressure na Sitwasyon

- Kaso: Onshore na Carbon Capture Storage na May Vacuum Cycling

- Paglalapat ng Safety Factors para sa Maaasahang Pagganap sa Ilalim ng Mababang Internal Pressure

-

Advanced Mechanical Modeling at Finite Element Analysis sa Casing System Design

- Hindi Pantay na Distrubusyon ng Tensyon sa Paligid ng Casing Dahil sa Interaksyon ng Semento-Formasyon

- Mga Pag-unlad sa Mekanikal na Pagguguhit ng Casing sa ilalim ng In-Situ Stresses

- Finite Element Analysis ng Casing-Cement-Formation System: Pagpigil sa Debonding at Microannuli

- Kaso: HPHT Well sa Tarim Basin na Napatunayan ng Buong-System FEA

- Pagsasama ng FEA at Field Data upang Ikonekta ang Agwat sa Pagitan ng Teorya at Pagganap

-

FAQ

- Ano ang pangunahing layunin ng pagkalkula ng casing pipe wall thickness sa ilalim ng panlabas na presyon?

- Paano nakatutulong ang ASME B31.3 standard sa pagkalkula ng kapal ng pader (wall thickness)?

- Bakit naging mas mahalaga ang real-time geopressure modeling para sa disenyo ng casing?

- Ano-ano ang ilang mahahalagang diskarte para maiwasan ang buckling at compression failures sa malalim na pag-install ng casing?

- Bakit mahalaga ang Do/T ratio sa pagkontrol ng mga pagbagsak ng casing pipe?

- Paano ang finite element analysis (FEA) ay nagbabago sa disenyo ng sistema ng casing?