What Are Drill Buckets and How Do They Work?

Core Functions in Foundation Drilling

Drill buckets handle three main jobs during foundation work: digging out earth, getting rid of debris, and forming those straight holes we need. They connect to big drilling machines and have teeth around the edges that chip away at whatever soil or rock gets in their path. As these buckets spin around, they scoop up all that loose material inside their empty center space. Once they're packed tight, workers pull them back up to dump the stuff somewhere else. This whole cycle keeps going until we've got those exact vertical openings needed for building supports, plus it stops the sides from caving in during the process. The way these buckets are built makes sure nothing gets stuck down there, which means cleaner digs and stronger bases for whatever structures go up later.

The Role of Drill Buckets in Modern Foundation Drilling

In modern foundation work, drill buckets have become the go-to solution for creating holes accurately across all sorts of soil types. Most contractors ditched the old manual digging approaches years ago since these machines can cut down construction time by around 40% when compared with what used to be standard practice. What really matters is how little they扰动 the ground during operation, which helps protect nearby buildings from damage. The consistent diameter holes produced are critical when installing those heavy duty support piles needed for skyscrapers and other tall structures. Drill buckets handle everything from dense clay to loose sand and even tricky mixed soils, making them a must-have tool for any serious infrastructure job where deep foundations are required for stability.

Key Design Features That Define Drill Bucket Performance

Drill bucket effectiveness depends on several engineered components:

- Cutting teeth configuration: Hardened steel teeth patterns optimized for specific soil types

- Bucket geometry: Cylindrical designs with capacity up to 8 cubic yards for efficient material retention

- Hinge mechanisms: Robust pivot systems enabling secure closure during material transport

- Wear protection: Abrasion-resistant coatings extending service life in rocky conditions

- Venting systems: Pressure-equalization features preventing material suction

These elements work to reduce drilling cycle times by 15–30% while maintaining borehole integrity. Proper tooth angle alignment decreases penetration resistance, while optimized bucket volume minimizes surfacing frequency. The hinge reliability ensures complete material discharge, preventing costly re-drilling operations.

Types of Drill Buckets and Their Soil-Specific Applications

Rotary Drilling Buckets for Stable Ground Conditions

Rotary drilling buckets work best when dealing with soils that stick together and more stable ground conditions such as thick clay layers or sand that's been bound together over time. The continuous spiral design helps remove dirt consistently from the hole being drilled. Recent research from 2023 suggests these methods can maintain around 95-98% intact boreholes in ground that doesn't collapse easily. What makes rotary buckets stand out is how little they shake during operation. This feature becomes really important on construction sites located close to buildings already standing there, where excessive shaking could damage nearby foundations or walls.

Soil Drilling Buckets: Adaptability Across Clay and Loam

Soil-specific buckets feature adjustable cutting teeth and staggered apertures to handle moisture variations in clay (15–35% water content) and loosely packed loam. A 2024 field trial showed a 30% productivity increase in mixed-soil conditions compared to generic buckets, attributed to their dynamic spoil-ejection design.

Rock & Sand Grab Buckets for Challenging Geologies

Engineered for fragmented rock layers and saturated sand, these buckets integrate carbide-tipped teeth and reinforced sidewalls. Recent analyses highlight their 40% faster material extraction rate in iron sand and pebble layers compared to conventional augers. Key innovations include:

- Dual-stage filtering to separate abrasive particles

- Pressure-balanced soil retention systems

Belling Buckets and Their Structural Advantages in Deep Foundations

Belling buckets create precision-enlarged bases for deep foundation elements, increasing bearing capacity by 50–70% in stable soils. Their articulating arms and real-time load sensors enable controlled soil displacement, reducing over-excavation risks by 65% (Geotech Solutions, 2023). These tools are indispensable for:

- High-load structures like suspension bridge piers

- Seismic-resistant foundations requiring optimized stress distribution

Applications of Drill Buckets in Foundation Construction Projects

Drill buckets play a foundational role in modern construction, enabling precise earth excavation across critical infrastructure projects. Their versatility addresses complex geotechnical challenges while maintaining structural integrity.

Drill Bucket Uses in High-Rise Building Foundations

In city skyline developments, these specialized tools really shine when dealing with those deep foundation piers that need to hold up massive vertical loads, sometimes over 15,000 kilonewtons worth of weight. The sealed construction helps keep things stable during digging operations in areas where groundwater is a problem for the soil structure. For tougher ground conditions, there are special rock auger versions that can actually dig sockets as deep as eight meters straight into solid bedrock beneath. What makes this particularly valuable is how much better it handles sideways movement problems. Tests show around a 40 percent reduction in lateral displacement issues compared with standard drilling techniques, which matters a lot in earthquake-prone regions where buildings need extra stability.

Efficient Piling in Bridge and Infrastructure Projects

When building bridges, engineers often turn to drill buckets to dig those 2.5 to 4 meter wide holes needed for foundation piers. These machines have these spiral shaped flights that can pull up between 18 and 25 cubic meters of dirt each hour right from riverbeds. They work much better than just digging open holes because they actually stabilize the sides of the bore while going faster at the same time. Looking at actual construction sites lately, crews report getting things done about 30 percent quicker when they switch to these special buckets designed with optimized torque and those clever interlocking cutters that handle all sorts of soil mixtures without clogging up so much.

Deep Foundation Projects and the Role of Specialized Tooling for Foundation Drilling

Belled shafts requiring 3:1 base-to-shaft ratios leverage telescoping buckets capable of expanding cutting diameters mid-operation. This technique increases end-bearing capacity by 60% in soft clays while reducing concrete overpour waste. For projects requiring depths beyond 50 meters, dual-chamber buckets with automated spoil ejection systems maintain drilling precision while minimizing equipment downtime.

How Drill Bucket Selection Enhances Drilling Efficiency

Proper drill bucket selection improves operational efficiency by 18–34% in foundation projects according to 2023 equipment utilization studies. Contractors who match bucket specifications to soil composition and structural requirements reduce rework rates by 27% while maintaining borehole accuracy within 2 mm tolerances.

Improving Drilling Efficiency Through Proper Equipment Selection

Geotechnical analysis determines optimal bucket configurations—90% of contractors report shorter project timelines when using shear-sensitive clay buckets in cohesive soils versus standard models. Soil-specific tooling minimizes energy waste, with helical flighting designs cutting torque requirements by 41% in sandy conditions.

Reducing Cycle Time with Optimized Bucket Design

Bulk plate geometry innovations achieve 22% faster spoil removal in prototype testing. Shortened cycle times stem from three design factors:

- Tungsten-carbide tooth clusters requiring 38% less downforce

- Variable pitch flighting that increases spoil velocity

- Modular wear pads extending service intervals by 120 operating hours

Case Study: Drilling Efficiency Gains Using Belling Buckets

A 2024 high-speed rail project demonstrated belling buckets completing foundation shafts 65% faster than conventional methods. The specialized tooling created 3.8m-diameter bell-outs in limestone bedrock with single-pass efficiency, eliminating secondary widening operations. Project managers recorded:

| Metric | Standard Method | Belling Buckets | Improvement |

|---|---|---|---|

| Completion Time per Shaft | 14.2 hours | 5.1 hours | 64% faster |

| Concrete Overuse | 12% | 3% | 75% reduction |

| Equipment Fuel Consumption | 87 liters | 62 liters | 29% savings |

Data-Driven Performance Optimization in Rotary Drilling Operations

Real-time drilling analytics platforms now achieve 94% match between predicted and actual bucket performance. Integrated strain gauges and inertial sensors enable automatic RPM adjustments when encountering soil density changes, maintaining optimal cutting efficiency across mixed geology layers.

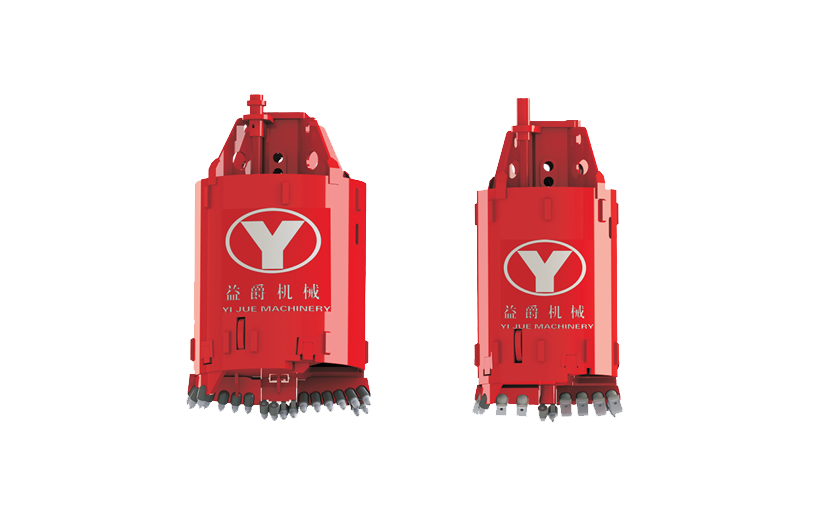

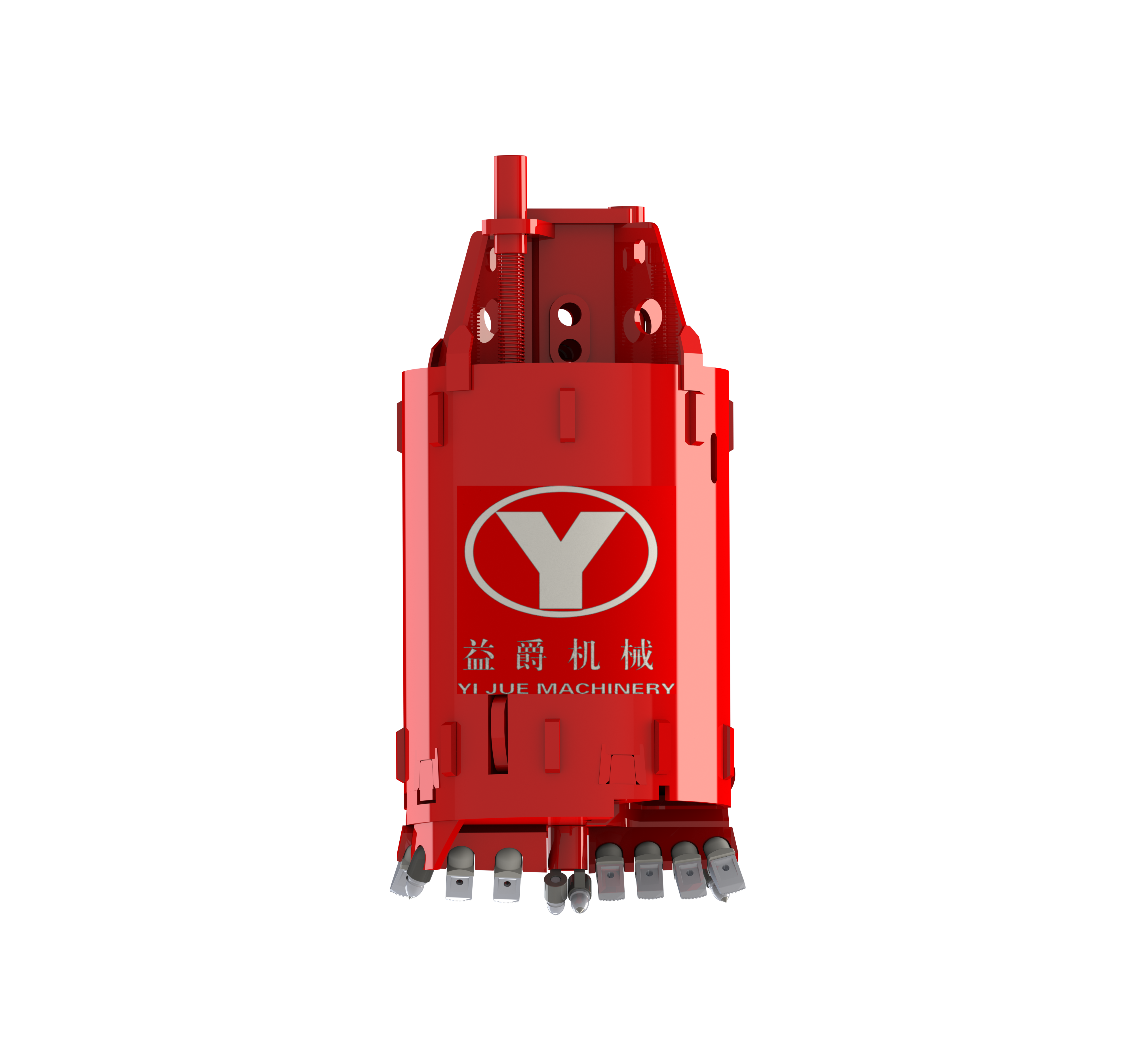

Innovations in Drill Bucket Technology by Wuhan Yi Jue Tengda Machinery Co., Ltd.

Engineering Advancements in Modern Drill Bucket Features and Design

The latest advances in engineering have really changed what drill buckets can do, thanks to better structural design and new materials. Using advanced computer modeling, engineers created cutting edges with tapers that cut down on soil sticking problems by about 40% when working with clay-like soils. Meanwhile, those special boron steel alloy teeth last around 2.5 years longer than regular ones before needing replacement. Another smart feature is the self cleaning flutes which stop dirt from building up during digging, so the hole stays straight and clean throughout the job. All these improvements tackle some big headaches for foundation drillers who often deal with broken welds and loose teeth causing downtime and extra costs.

How Wuhan Yi Jue Tengda Optimizes Drilling Efficiency and Performance

The company has developed some unique manufacturing methods that actually deliver real improvements in how rotary drills perform on site. What really stands out is their special hydraulic sync system which matches the bucket's spinning motion with the downward pressure applied during drilling. This coordination cuts down on average cycle times by around 18% when working through tough underground layers. When we look at actual field testing across different rock types, operators saw about 30% less torque needed while boring through mixed ground conditions. That means less fuel burned and less stress on the machinery itself. They've also worked on coating technologies for drill bits that hold up better against sand abrasion. Contractors report roughly 22% fewer days lost to maintenance in infrastructure pile driving jobs where these coated bits are used regularly.

Table of Contents

- What Are Drill Buckets and How Do They Work?

- Types of Drill Buckets and Their Soil-Specific Applications

- Applications of Drill Buckets in Foundation Construction Projects

- How Drill Bucket Selection Enhances Drilling Efficiency

- Innovations in Drill Bucket Technology by Wuhan Yi Jue Tengda Machinery Co., Ltd.