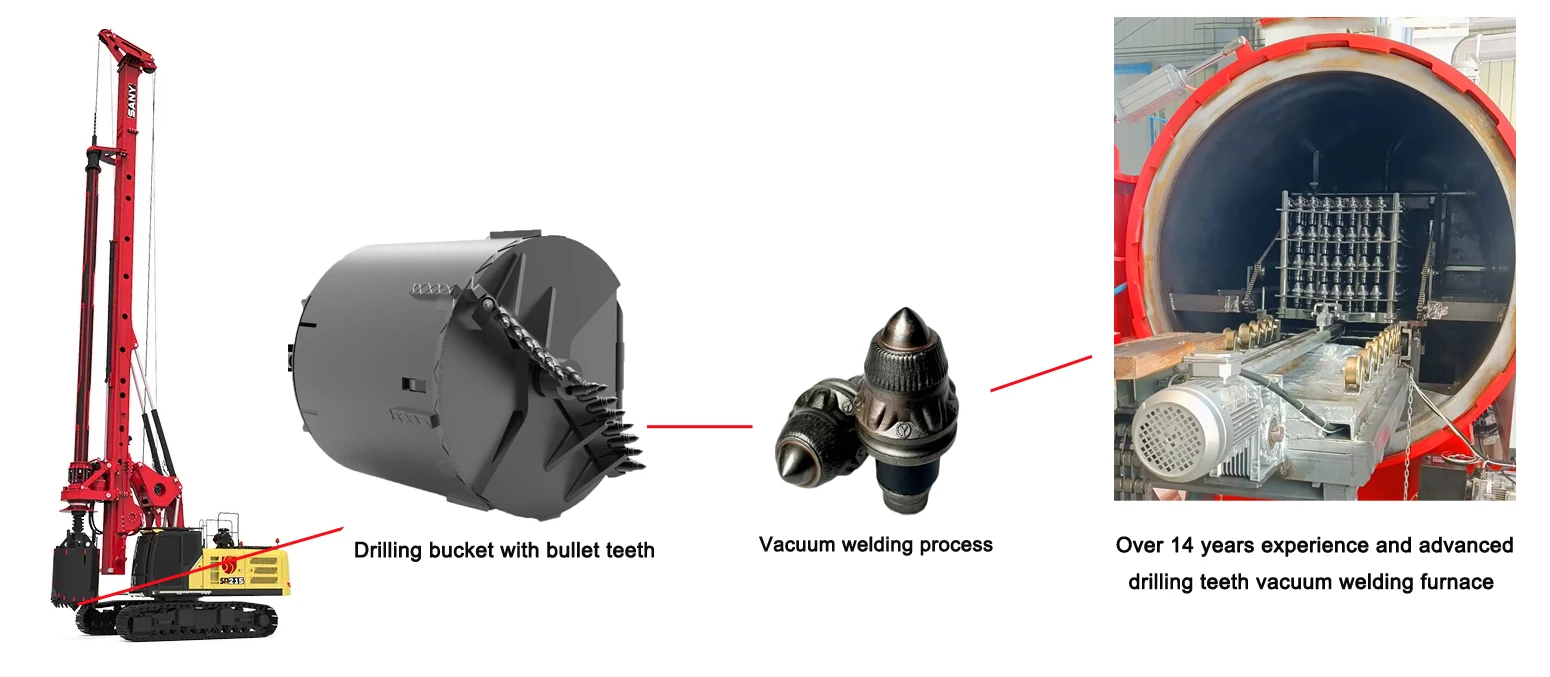

1.Tungsten carbide inserts Use large-grain coarse-grained tungsten carbide, which has high wear resistance, impact resistance and

thermal stability,

2.Shank body High-quality alloy steel is selected, and the stable heat treatment process makes the tooth body

wear-resistant and tough,

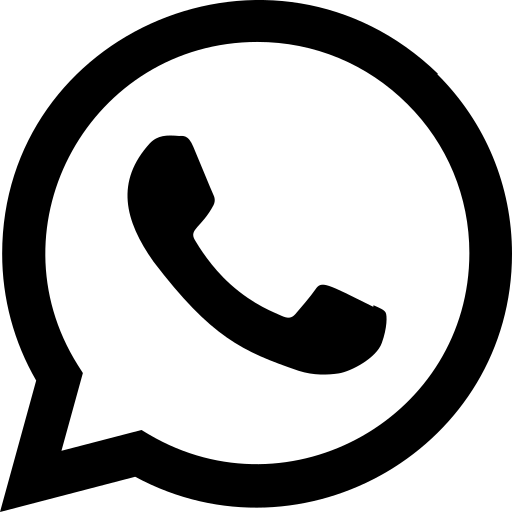

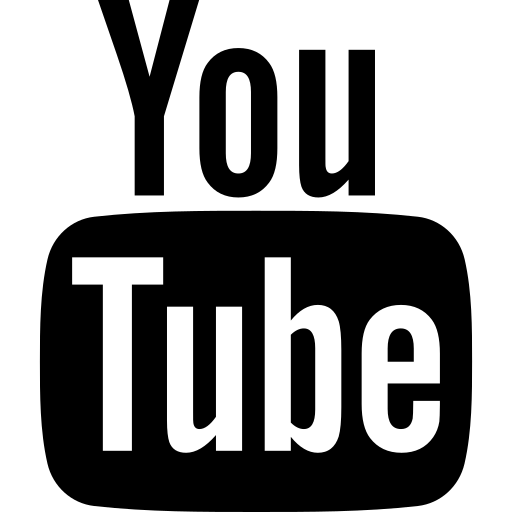

3.Brazing process Through special welding process, the strength of pick welding is increased, the impactresistance is improved, and the carbide tip is not easy to fall off,

4.Shank reinforcement Through laser cladding, powder metallurgy technology and other technologies to protect the head of the tooth body, reduce the wear rate and extend the service life.