Weld-On Excavator Bucket Teeth: Engineered for Extreme Digging Performance

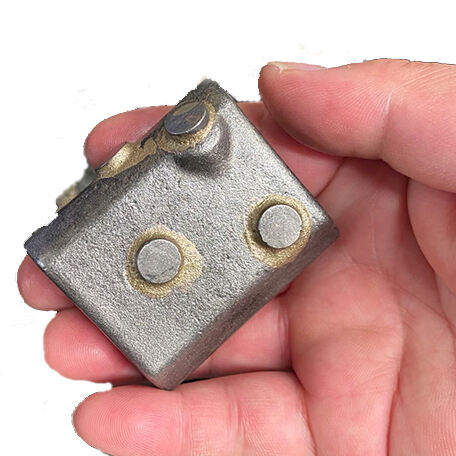

Weld-on excavator bucket teeth are the essential, permanent digging points affixed directly to an excavator's bucket lip. This design creates an incredibly strong, single-unit structure that eliminates the failure points—like pins and adapters—found in other systems. They are the preferred choice for operators who demand maximum rigidity and reliability from their machine, especially when tackling consistent, high-impact materials that would quickly compromise mechanical connections.

The application prospects for these teeth are defined by the excavator's versatile role. They are fundamental in rocky trenching and general excavation, providing the necessary penetration strength to break through hardpan and shale. In demolition and site clearing, their solid-welded construction withstands the shocking impact of breaking concrete and navigating rebar. Furthermore, they excel in quarry and mining applications, offering exceptional abrasion resistance when handling heavy aggregates and ore, significantly reducing downtime for changes compared to simpler tooth systems.

Selecting the right weld-on tooth is a direct investment in productivity and cost-management. Their simplicity means a lower initial cost than adapter systems and reduced inventory, as only the tooth itself needs replacement. By choosing a profile and alloy matched to your primary material—whether a long point for clay or a reinforced blunt tip for rock—you protect the bucket's base structure, maintain optimal digging force, and keep your excavator operational where it matters most: on the job site.

Copyright © Wuhan Yi Jue Tengda Machinery Co., LTD